Founded in 2008, we are mainly engaged in the

research and development, production and sales

of all kinds of insulating tubes.

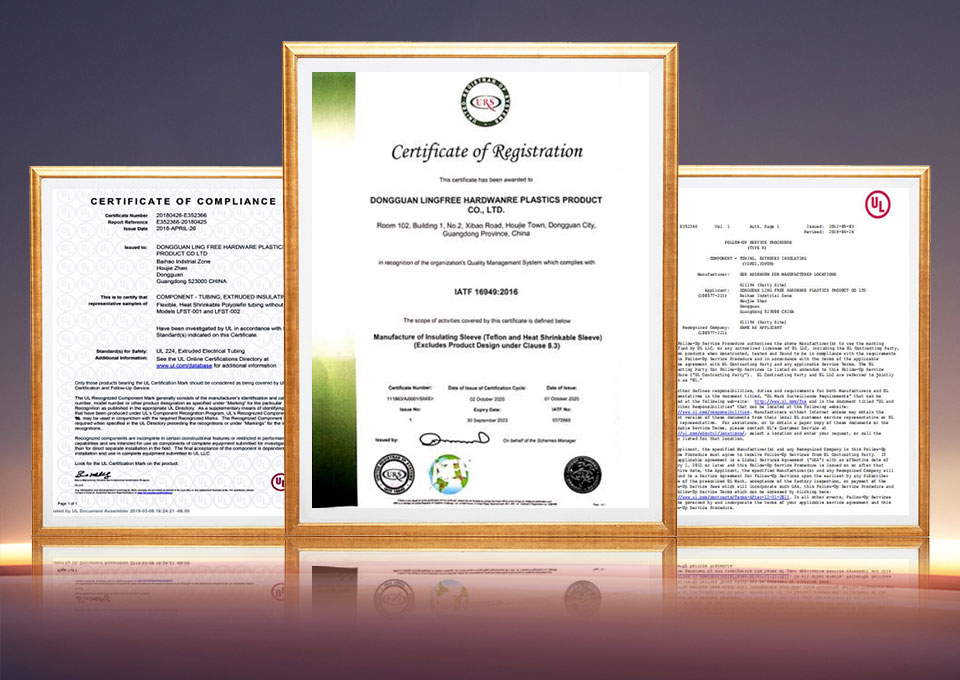

The company has a strong R & D team, the industry's leading production equipment and

test equipment, after more than 10 years of steady development, in the joint efforts of all

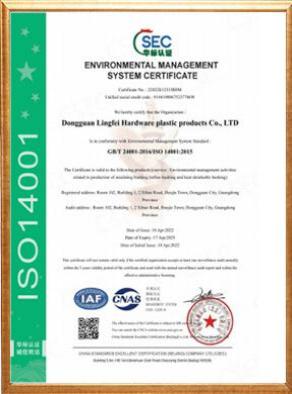

employees, the company has obtained the IATF16949 automotive quality management

system, ISO14001 environmental management system, ISO9001 quality management

system certification. In December 2018, we successfully obtained the honorary title of

"National High-tech Enterprise".

The company's main products include: fiberglass tubing,UL heat-shrinkable tubing,

new energy heat-shrinkable tubing, double-wall heat-shrinkable tubing with adhesive,

Teflon tubing polytetrafluoroethylene (PTFE), braided retractable mesh tubing, PVC

tubing, corrugated tubing, the research and development of insulating materials,

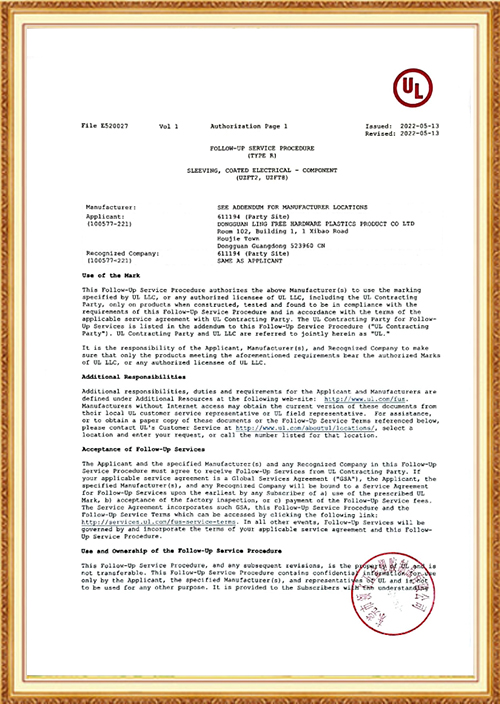

production and sales. Our products have passed UL, CSA safety certification (certification

number E352366, E520027). At the same time, all products comply with EU RoHS 2.0 and

REACH test report.

English

English