Nylon Braided Hose is an essential component in many industries due to its durability, flexibility, and resistance to extreme conditions. Whether used in automotive, industrial, or hydraulic systems, these hoses ensure secure fluid transfer with excellent pressure resistance. Our collection includes PA66 Braided Hose, Nylon Reinforced Hose, High-Pressure Nylon Braided Hose, and Flexible Nylon Braided Hose, each designed for specific applications.

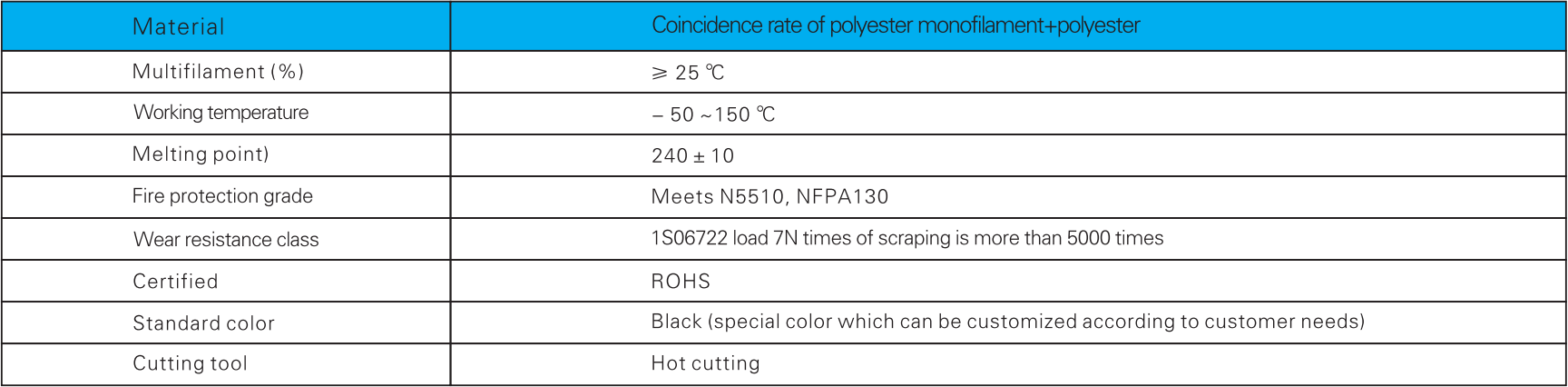

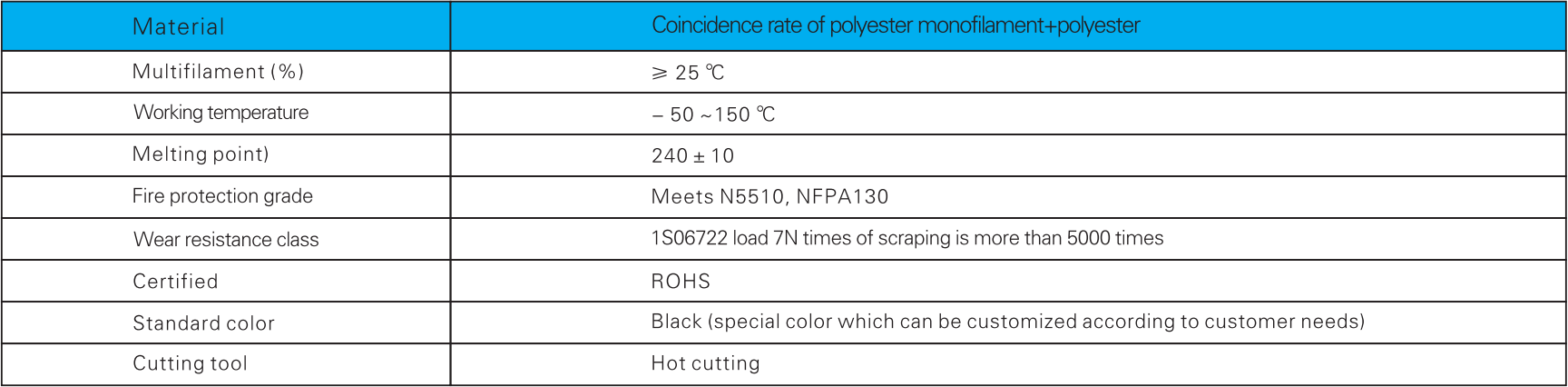

Specification

Dimension

Key Features of Our Nylon Braided Hose1. High Strength and Pressure Resistance

Manufactured using high-quality PA66 material, our Nylon Braided Hose offers exceptional tensile strength, making it suitable for high-pressure applications. The reinforced nylon structure ensures stability even under extreme conditions, preventing leaks and bursts.

2. Superior Flexibility and Durability

The Flexible Nylon Braided Hose is designed for easy handling and installation, reducing the risk of kinks or cracks. It maintains structural integrity even under dynamic movement, making it ideal for automotive and machinery applications.

3. Heat and Chemical Resistance

Our Nylon Reinforced Hose is resistant to heat, chemicals, and abrasions, ensuring long-term performance in demanding environments. It can withstand high temperatures and exposure to oils, fuels, and other harsh substances, making it a reliable choice for industrial applications.

4. Weatherproof and UV-Resistant

For outdoor use, our High-Pressure Nylon Braided Hose is engineered to withstand extreme weather conditions. With UV-resistant and weatherproof properties, it remains durable even under prolonged sun exposure, humidity, and temperature fluctuations.

Versatile Applications of PA66 Braided Hose

Our PA66 Braided Hose is widely used in various industries due to its strength, flexibility, and chemical resistance. Some common applications include:

Automotive Industry – Used in fuel lines, brake systems, and coolant transfer for vehicles.

Hydraulic Systems – Ensures efficient fluid transfer in heavy-duty machinery and industrial equipment.

Pneumatic Applications – Ideal for compressed air systems requiring high pressure and durability.

Chemical and Fuel Handling – Resistant to corrosive substances, making it perfect for chemical plants and fuel transport.

Marine and Outdoor Use – The UV-resistant and weatherproof design makes it ideal for boats, irrigation systems, and outdoor machinery.

Why Choose Our High-Pressure Nylon Braided Hose?

We prioritize quality, performance, and durability in all our hose solutions. Our Nylon Braided Hose collection offers:

Premium PA66 and Nylon Reinforced Construction – Engineered for superior strength and longevity.

Flexible and Lightweight Design – Easy to handle and install in various industrial and commercial setups.

High-Pressure Resistance – Suitable for demanding applications with extreme pressure conditions.

UV, Heat, and Chemical Resistance – Ensures long-lasting performance in harsh environments.

Order Your Nylon Braided Hose Today

Whether you need a PA66 Braided Hose for industrial machinery, a Nylon Reinforced Hose for automotive applications, or a High-Pressure Nylon Braided Hose for hydraulic systems, we have the perfect solution. Browse our selection and place your order today for reliable, high-performance hose solutions. Contact us for bulk orders and wholesale inquiries!

FAQ:

What is a nylon braided hose?

A nylon braided hose is a hose with an outer layer made of braided nylon fibers and an inner layer usually made of rubber or plastic, combining resistance to abrasion and high pressure.

What are the main benefits of nylon braided hose?

Key benefits include high pressure resistance, abrasion resistance, good chemical resistance, high temperature resistance and flexibility.

What applications are nylon braided hoses used for?

Commonly used in liquid and gas transportation systems such as automotive cooling systems, hydraulic systems, air compressors, misting systems and industrial machinery.

What is the operating temperature range of nylon braided hose?

The operating temperature range of nylon braided hose is typically between -40°C and +100°C, but the exact range may vary depending on the manufacturer and material.

How do I choose the right type of nylon braided hose?

Selection requires consideration of the hose's inside diameter, operating pressure, operating temperature, and whether additional chemical or abrasion resistance is required.

What is the pressure resistance of a nylon braided hose?

Nylon braided hose is typically highly pressure resistant, with the braided nylon layer reinforcing the hose's structural strength and allowing it to withstand high internal pressures.

Does braided nylon hose require any special maintenance?

The integrity of the hose needs to be checked periodically to ensure that there is no abrasion, cracks or fluid leaks. Avoid exposing the hose to extreme environmental conditions to prolong its life.

What are the common materials used for nylon braided hose?

Common materials include polyurethane (PU), polyester (PET), fluoroelastomer (FKM) and silicone (SI), which offer different performance characteristics.

How do I install a nylon braided hose?

Installation should ensure that the hose connections match the equipment and are secured with appropriate fittings and clamps. Avoid bending or compressing the hose to prevent performance degradation or damage.

What is the chemical resistance of nylon braided hose?

Nylon braided hose has good resistance to many chemicals, but may not be durable enough for some strong acids or bases. Specific chemical resistance should be selected based on the type of media used in the actual application.

English

English