In today’s fast-paced technological world, ensuring the longevity and safety of cables and wires is essential across various industries. Whether you are dealing with automotive, electrical, or industrial applications, having the right protective solution for your cables is paramount. Self-Closing Sleeving has emerged as a preferred choice for professionals seeking efficient cable management. As a trusted Self-Closing Sleeving Supplier, we offer high-quality Self Rolling Braided Mesh Tubes and Self-Closing Sleeving that are designed to provide optimal protection and organization.

What is Self-Closing Sleeving?

Self-Closing Sleeving, also known as Self Rolling Braided Mesh Tubes, is an innovative solution designed to offer seamless protection for cables, wires, and hoses. It features a self-closing mechanism that securely wraps around the cables, preventing them from tangling, abrasion, or exposure to harsh elements. This versatile product is widely used in a variety of industries, including automotive, electrical, and electronics.

Benefits of Self-Closing Sleeving

Superior Protection: Self-Closing Sleeving acts as a shield for cables, protecting them from mechanical damage, abrasion, and chemical exposure. It is ideal for sensitive wiring in automotive, industrial, and electrical settings.

Heat Resistance: Many self-closing sleeving options come with heat shrinkable sleeving properties, providing resistance to high temperatures and preventing damage from heat exposure.

Easy Installation: The self-closing feature makes it incredibly easy to install. It can be applied without any tools, and it securely wraps around cables, offering a snug fit without slipping off.

Reusable: Reusable Cable Sleeving offers an eco-friendly solution for cable management. You can remove and reuse the sleeving multiple times, reducing waste and contributing to a sustainable environment.

Flexible and Expandable: With its expandable design, Self-Closing Wire Loom can accommodate cables of various sizes, providing flexibility and adaptability in different environments.

Applications of Self-Closing Sleeving

Cable Protection: Self-Closing Sleeving is widely used in electrical applications to safeguard wires from damage and wear. It provides protective sleeving for cables, enhancing the durability of wiring systems.

Automotive Industry: In the automotive sector, it is used to manage and protect vehicle wiring from heat, abrasion, and dirt.

Industrial Applications: Self-Closing Sleeving is crucial in industrial settings where cables need protection from chemicals, oils, and rough environments.

Electronics: Used in electronic devices and appliances, it ensures that the internal wiring remains intact and functional.

Selection Advice

When selecting Self-Closing Sleeving, users should choose the right product according to their actual needs and environmental conditions. For example, it is necessary to consider factors such as the size, shape, material and required level of protection of the cable or harness. It is also necessary to select a manufacturer or supplier with a good reputation and reliable quality to ensure the quality and performance of the product.

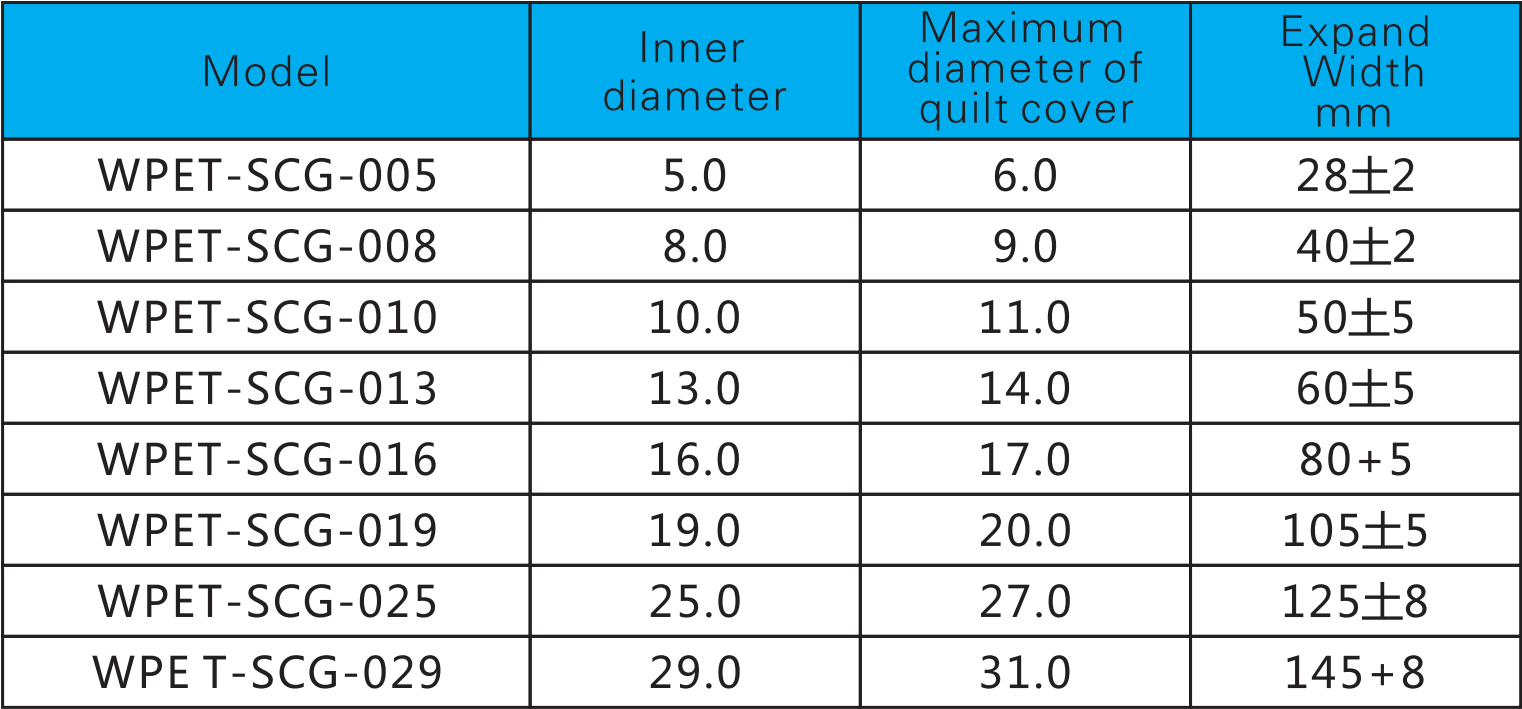

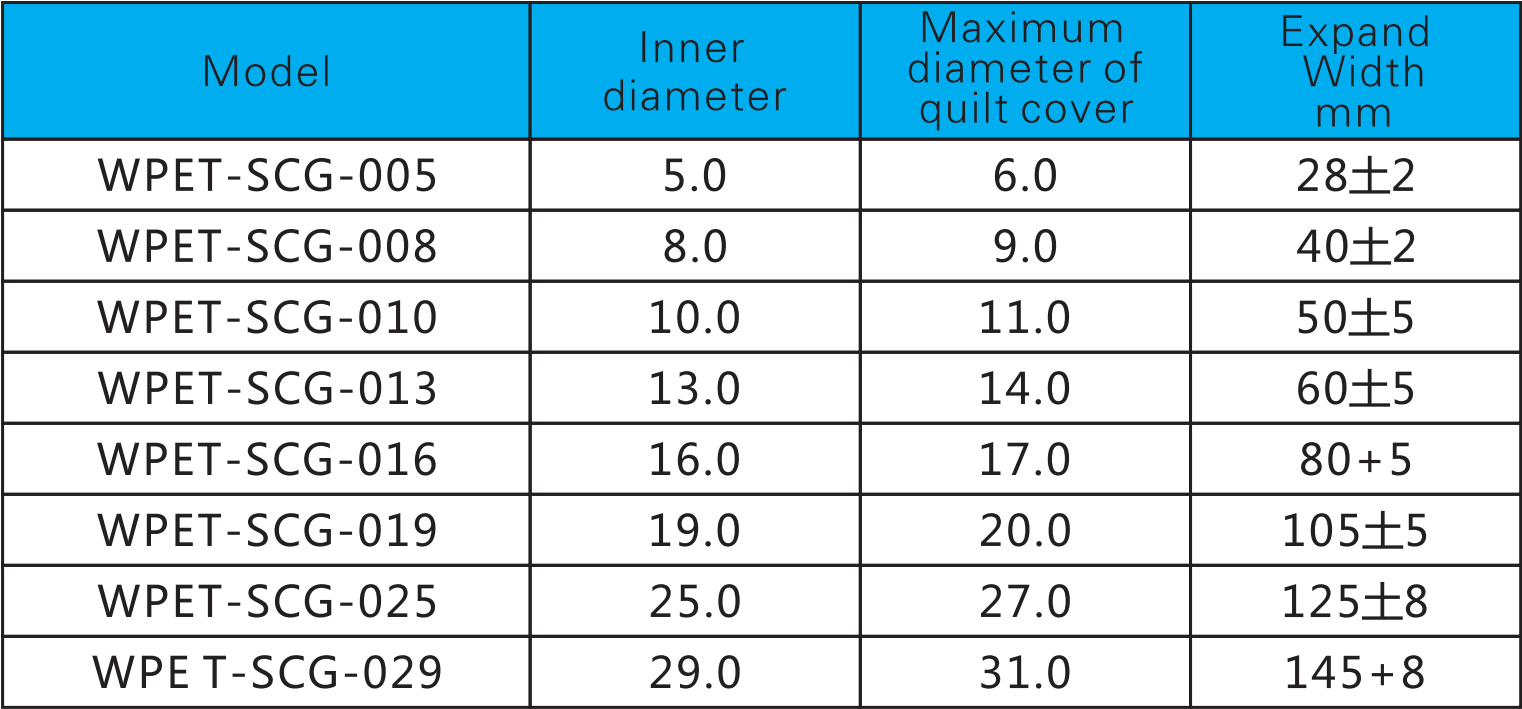

Dimension

Why Choose Our Self-Closing Sleeving?

As a leading Self-Closing Sleeving Supplier, we are committed to providing top-notch products that meet the needs of our customers. Whether you require Self-Closing Sleeving OEM for custom projects or bulk orders, we have the capacity to deliver high-quality solutions tailored to your specifications.

Customization: We offer Self-Closing Sleeving OEM services, allowing you to get custom sizes, colors, and materials that best suit your specific requirements.

Durable Materials: Our products are made from high-quality materials that ensure long-lasting performance and protection. They are designed to withstand the most demanding conditions.

Bulk Supply: We specialize in providing Self-Closing Sleeving and Self Rolling Braided Mesh Tube solutions in large quantities, catering to both small and large-scale industrial needs.

Applications of Our Self-Closing Sleeving Products

Heat Shrinkable Sleeving: Ideal for protecting wires and cables that need additional heat resistance.

Cable Protection Sleeving: Protects cables from various environmental factors such as moisture, dirt, and mechanical damage.

Protective Sleeving for Cables: Offers a barrier against physical damage, ensuring that cables maintain their functionality over time.

FAQ:

What is Self-Closing Sleeving?

Self-Closing Sleeving is a self-shrinking protective tube that is used to wrap cables or wires to provide additional protection.

What are the main functions of Self-Closing Sleeving?

The main functions include protecting the cable from abrasion, chemical attack and environmental factors, as well as providing insulation and organizing the cable.

In which applications is Self-Closing Sleeving suitable?

For industrial, electrical, automotive and aerospace applications, especially in environments where cables and conductors need to be protected.

What materials are available for Self-Closing Sleeving?

Common materials include polyester, nylon, polyurethane, etc., which offer varying degrees of abrasion resistance and insulation.

How do I choose the right size of Self-Closing Sleeving?

Consider the diameter of the cable and the percentage of shrinkage required to ensure that the Sleeving wraps tightly around the cable.

Is Self-Closing Sleeving complicated to install?

Installation is relatively simple, simply stretch the Sleeving over the cable and allow it to self-contract to hold it in place.

How does Self-Closing Sleeving provide protection?

It protects against mechanical abrasion, chemical attack and environmental factors by tightly wrapping around the cable, while also providing some insulation.

Is Self-Closing Sleeving flame retardant?

Some Self-Closing Sleeving products are flame retardant, but this depends on the materials used and manufacturing standards.

What is the temperature range of Self-Closing Sleeving?

The temperature range depends on the material, generally from -40°C to +150°C, depending on the product specification.

Is Self-Closing Sleeving reusable?

In general, Self-Closing Sleeving is a single-use product, but in some applications it can be reused if it is not damaged.

English

English