Double Wall Heat Shrink Cap is a double wall Heat Shrink Cap used to cover the splices or connections of cables, wire harnesses or other equipment. Its double-layer structure includes an inner layer of hot melt adhesive and an outer layer of heat shrink material, which can provide excellent sealing performance and durability. By heating, the hot melt glue forms a seal between the cover and the connecting part, and the outer layer of heat shrinkable material can tightly wrap and secure the connecting part after heating, providing additional protection and insulation. Double wall heat shrink cap is usually used in electrical, communications, automotive and other industries to waterproof, moisture-proof, insulate and protect connecting parts.

Characteristics

Double-wall structure: It has a double-wall design, with the inner layer made of hot melt adhesive and the outer layer made of heat shrinkable material.

Excellent sealing performance: The inner layer of hot melt adhesive forms a seal after heating, preventing moisture and other external substances from penetrating into the connecting part.

Durability: The outer layer of heat shrink material provides an extra layer of protection, enhancing the durability and wear resistance of the connected parts.

Easy to Install: By applying heat, the Double wall heat shrink cap can be installed quickly and simply on the connecting parts, and forms a strong seal after cooling.

Excellent insulation properties: The outer heat shrinkable material has good insulation properties and protects the connecting parts from electrical faults.

Widely used: Suitable for electrical, communications, automotive and other industries, used for waterproofing, moisture-proof, insulation and protection of connecting parts.

Customizable sizes and specifications: According to specific needs, Double wall heat shrink caps can be provided in various sizes and specifications to meet the needs of different applications.

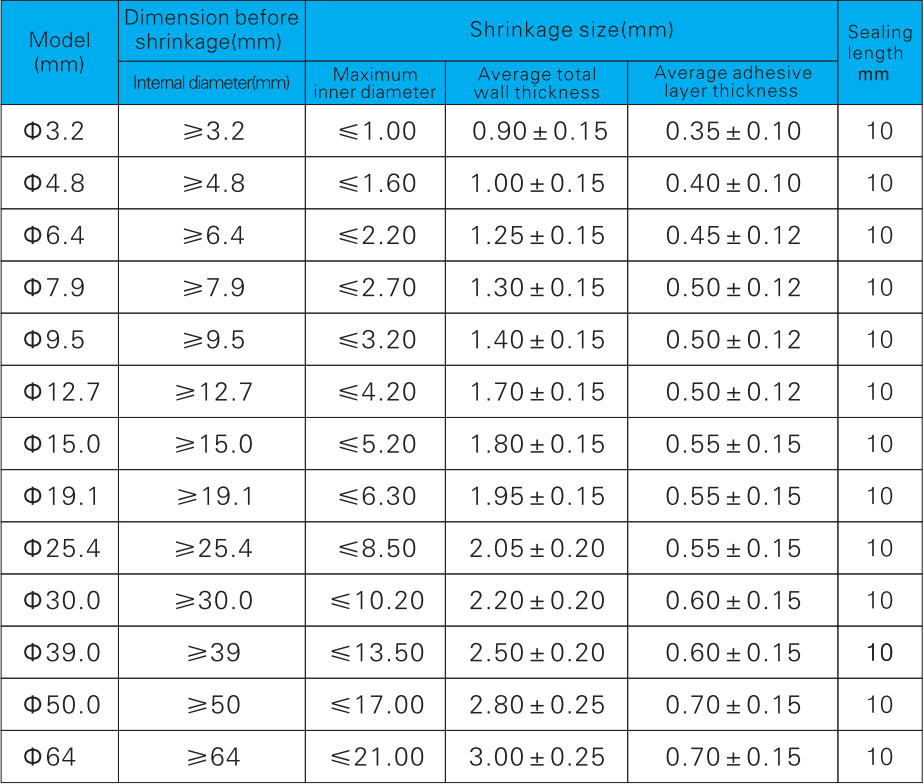

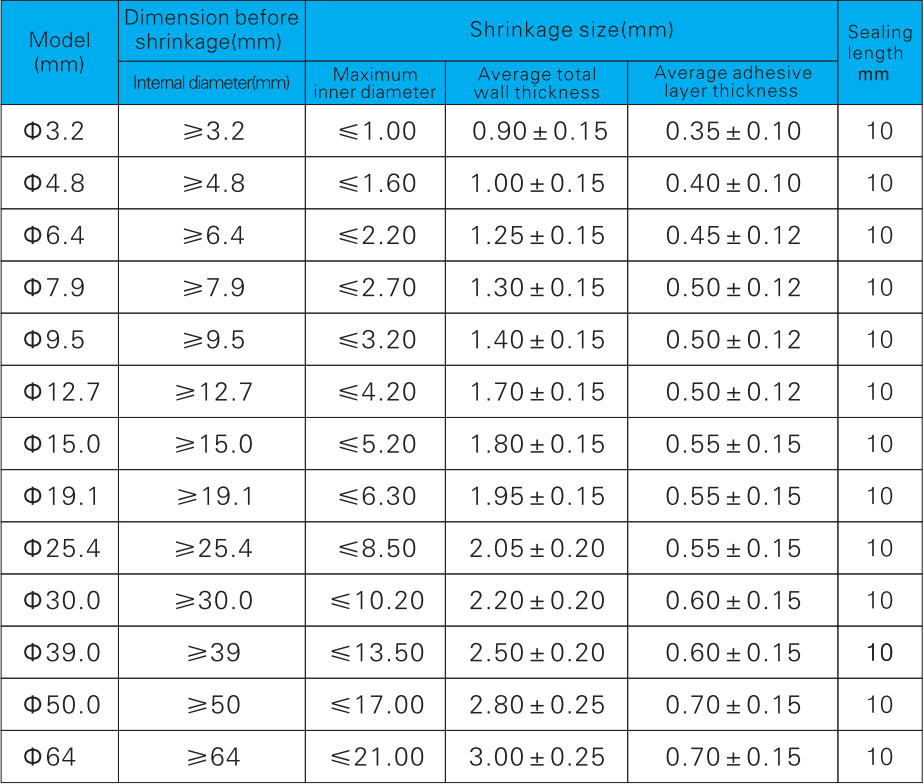

Dimension

Key Features

1.Dual-Layer Structure

Outer Layer: Made of cross-linked polyolefin, providing excellent wear resistance, durability, and protection against external mechanical stress.

Inner Layer: Coated with adhesive material that melts and flows upon heating, creating a watertight and corrosion-resistant seal.

2.Superior Insulation Properties

The cap delivers high electrical insulation, preventing short circuits and electrical leakage.

3.Environmental Resistance

Resistant to moisture, dust, and chemicals, ensuring long-term protection even in harsh conditions.

4.Wide Application Range

Suitable for various cable diameters and types, with flexibility to shrink and conform securely to the application.

5.Easy Installation

Quick and straightforward to apply using a standard heat gun, saving time and labor costs.

Advantages of Double Wall Heat Shrink Caps

1.Reliable Sealing: The inner adhesive layer ensures a secure and waterproof seal.

2.Enhanced Durability: The tough outer layer resists environmental and mechanical wear.

3.Wide Compatibility: Available in various sizes and colors for diverse applications.

4.Cost-Effective: Long service life reduces the need for frequent replacements or repairs.

Applicable Scenarios

1. Cable Terminal Protection: Widely used in sealing and protecting various cable terminals from water, dust and chemical substances.

2. Automotive wiring harness: Suitable for wiring harness protection in the automotive industry to ensure the stability of electrical connections in harsh environments.

3. Electrical equipment: suitable for insulation and mechanical protection of wires and connection points in electrical and electronic equipment.

4. Marine engineering: especially suitable for cable connection protection in ships and marine environment, corrosion-resistant, waterproof and UV-resistant.

FAQ:

What is a double wall heat shrink cap?

Double wall heat shrink caps are protective covers used to seal the ends of cables and wire harnesses. It is constructed of two layers of material: an outer layer of heat-resistant, insulating polyolefin material and an inner layer of hot-melt adhesive. When heated, the outer layer shrinks and the inner layer melts and adheres to the cable or harness, providing waterproof, moisture-proof and insulating protection.

What is the main use of double wall heat shrink caps?

Double-wall heat shrink caps are primarily used to seal and protect the ends of cables and wire harnesses from moisture, dust, chemicals and mechanical damage. It is widely used in electrical engineering, automotive industry, shipbuilding industry and communication equipment.

What is the difference between double-wall heat shrink caps and ordinary heat shrink tubing?

Double-walled heat shrink caps are specifically designed to seal cable ends, featuring a cap shape and a hot melt adhesive inner layer to provide a better seal. Ordinary heat shrink tubing is usually used for insulation and protection of the middle part of the cable and does not have the shape and sealing function of the cap.

How to properly install double wall heat shrink caps?

When installing a double wall heat shrink cap, first select the appropriate size to ensure the cap will fit over the end of the cable. Then use a heat gun to evenly heat the cap so that the outer layer shrinks and clings to the cable, and the hot melt glue in the inner layer melts and seals the cable end.

What is the main material of double wall heat shrink cap?

The outer material of double-wall heat shrink caps is usually polyolefin (Polyolefin), which has excellent heat resistance and insulation properties. The inner material is hot melt adhesive (Hot Melt Adhesive), which melts and adheres to the cable when heated, providing sealing protection.

Are double wall heat shrink caps waterproof?

Yes, double wall heat shrink caps have excellent waterproof properties. The inner layer of hot melt adhesive melts and adheres to the cable when heated, forming a waterproof seal that prevents water and moisture from entering.

Are double wall heat shrink caps flame retardant?

Many double-wall heat shrink caps are flame retardant and will self-extinguish when the fire source is removed. Flame retardant properties depend on the materials used and manufacturing standards.

How to choose the right double wall heat shrink cap?

Several factors should be considered when selecting a suitable double-wall heat shrink cap: the cable's diameter, shrink ratio, operating temperature range, application environment (such as whether waterproofing, corrosion protection, or flame retardancy is required), and required length. Select the appropriate size double-wall heat shrink cap based on specific application needs to ensure optimal sealing and protection.

English

English