Dual wall heat Shrink Tube is a double-wall heat Shrink Tube with an inner layer made of hot melt adhesive and an outer layer made of heat shrink material. This kind of pipe is suitable for electrical, communications, automotive and other fields to protect the connection parts of cables, wiring harnesses or other equipment. During the installation process, through heating, the inner layer of hot melt glue can form a seal between the pipe and the connecting part, while the outer layer of heat shrink material can tightly wrap the connecting part, providing additional waterproof, moisture-proof and insulating protection. Dual Wall Heat Shrink tube is a commonly used protective material due to its excellent durability, insulation properties and ease of installation.

Specification

Elongation at break New energy heat shrinkable sleeve Dimensions offinished products Watch strap adhesive Heat shrinkable sleeve The outerlayer of the sleeve is made of high-quality cross-linked polyene strangematerial and the inner layer is made of hot melt adhesive The outer layerhas the advantages of insulation, corrosion resistance and wear resistancewhile the inner laver has the advantages of low melting point, waterproosealing and mechanical strain buffering.lt is widely used in waterprooand air leak proof wiring of electronic equipment, sealing and fixing ofWire branches,anti-corrosion protection of metal pipelines, waterproofwiring of wire pumps and submersible pumps, etc.

Characteristics

Scope ofapplication:-45℃~125℃;

Theinitialshrinkage temperatureis 70° c,and the minimumcompleteshrinkagetemperatureis 125℃;

Melting temperature ofinner rubber layer:70℃~100℃;

Shrinkage ratio 2:1,3:1,4:1,axialshrinkage ≤+8%;

Sealing, waterproof, strain buffering,environmental protection(RoHS),self extinguishing of outer layer;

lt is convenient to use and can be shrunk by heating with an oven and a hot air gun.

Standard color: black (other colors can be provided according to customer requirements).

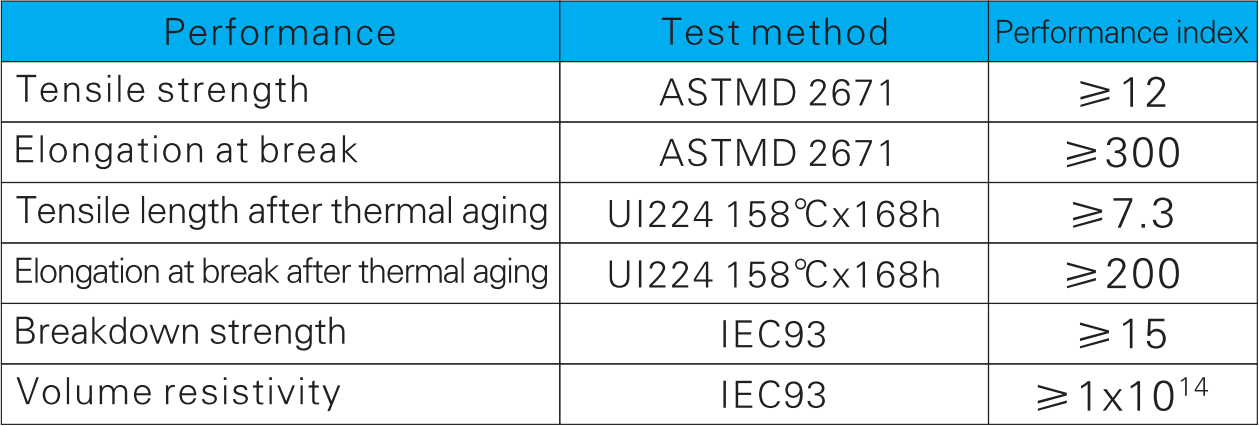

Performance Characteristics

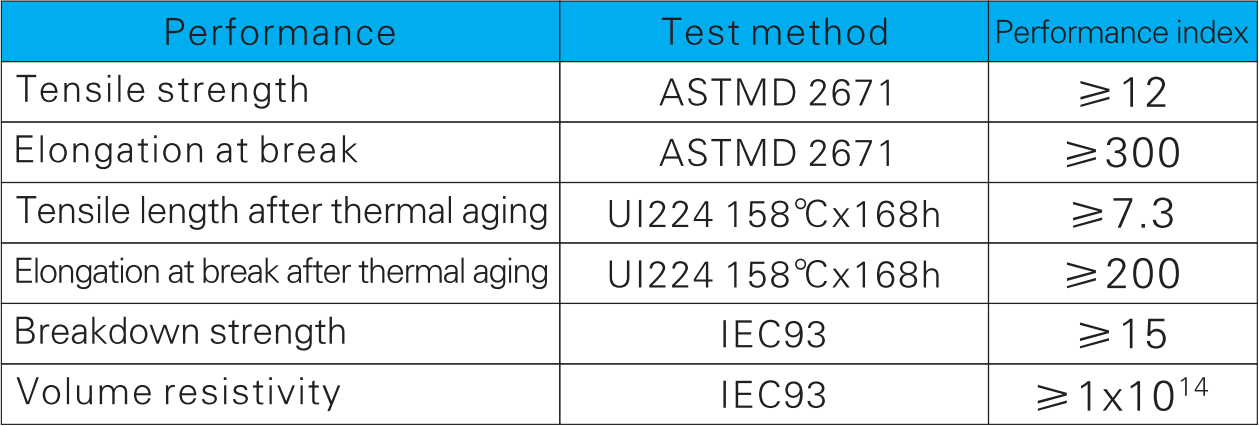

Adhesive characteristics

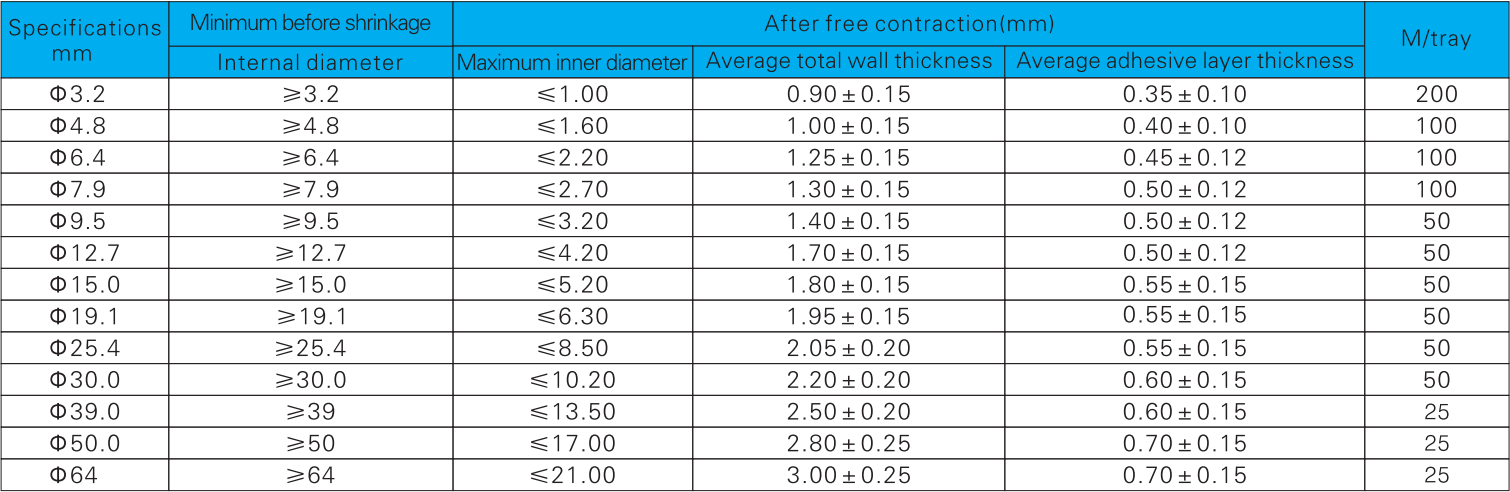

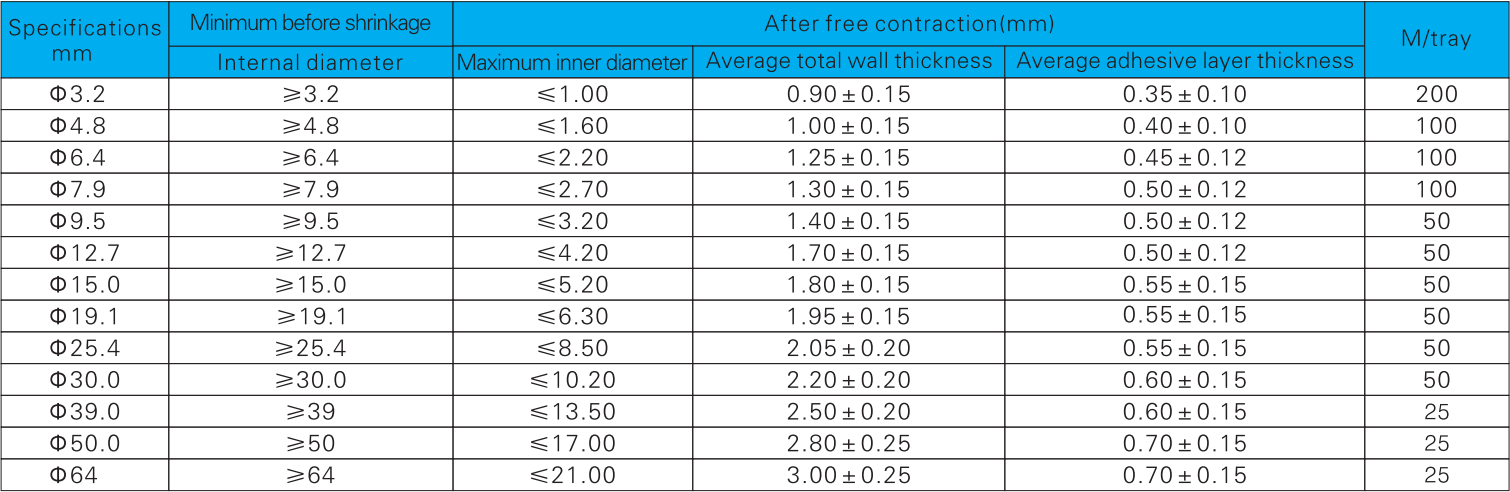

Dimension table 1(3:1)

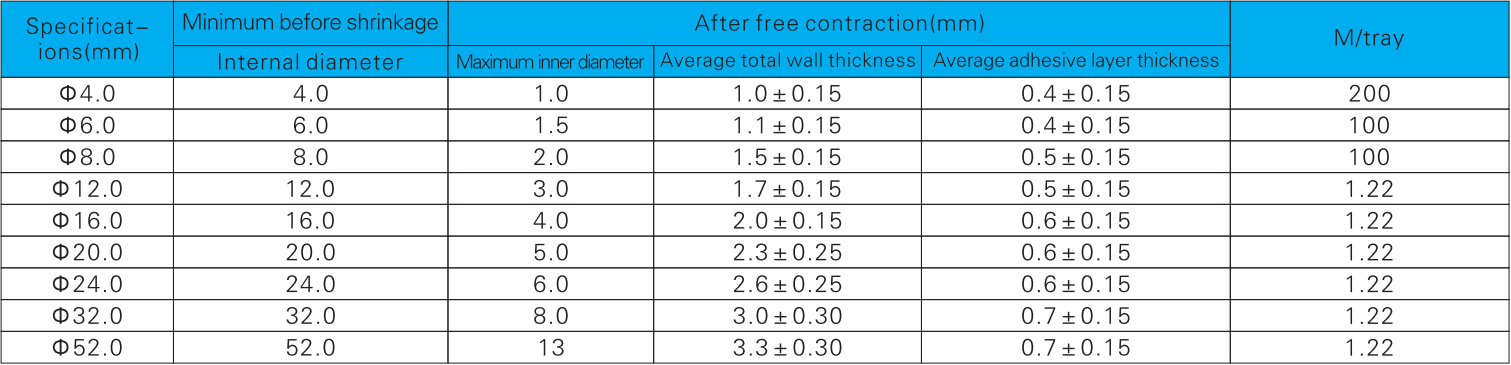

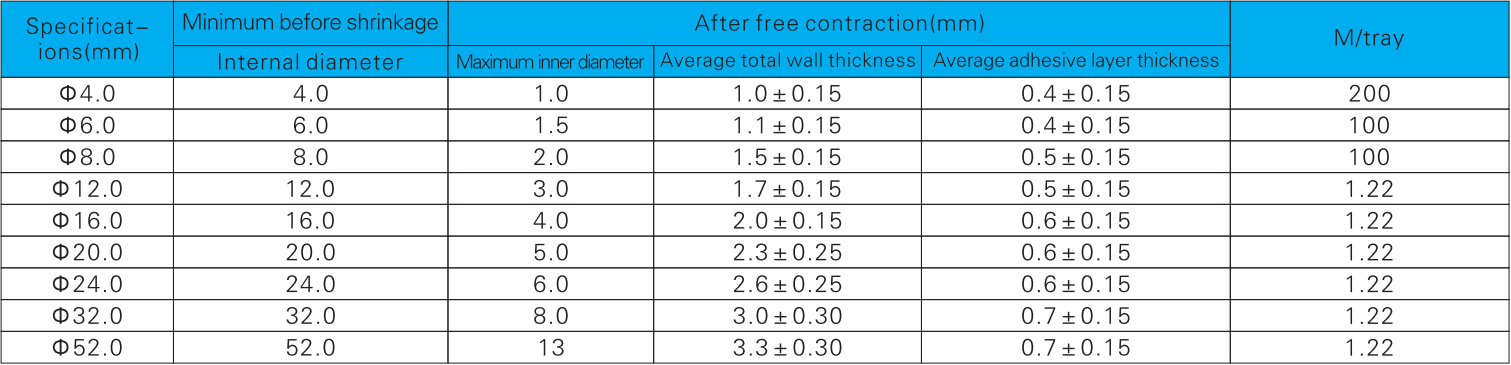

Dimension table 2(4:1)

Key Features:

Two-layer design: Outer heat-shrinkable layer and inner adhesive layer.

Moisture resistance: Seals out moisture and prevents corrosion.

Enhanced durability: Provides long-lasting protection in harsh environments.

Applications: Used for insulation, wire harnessing, and environmental sealing in electrical and automotive industries.

Shrink ratio: Common shrink ratios include 2:1, 3:1, and more.

Benefits:

Protection from environmental factors: Excellent for sealing against moisture, chemicals, and other contaminants.

Improved reliability: Ensures high-performance connections in critical applications.

Ease of use: Simple installation by applying heat, making it user-friendly.

Versatility: Available in different sizes and colors to suit various needs.

FAQ:

What is Dual Wall Heat Shrink Tube?

Dual Wall Heat Shrink Tube is a heat shrink tube made of two layers of material. The inner layer is usually hot melt adhesive or sealant, and the outer layer is a heat-resistant, insulating polyolefin material. When heated, the outer layer shrinks and the inner layer melts and adheres to the cable or connection point, forming a waterproof and moisture-proof seal.

What is the main use of Dual Wall Heat Shrink Tube?

Dual Wall Heat Shrink Tube is mainly used for insulation protection, mechanical protection, waterproof sealing and chemical corrosion resistance of cables and wire harnesses. It is widely used in the automotive industry, shipbuilding industry, electrical engineering and communications fields.

What is the difference between Dual Wall Heat Shrink Tube and Single Wall Heat Shrink Tube?

Dual Wall Heat Shrink Tube has a two-layer structure, the inner layer is hot melt adhesive, which provides waterproof and moisture-proof functions, while single-wall heat shrink tube has only one layer of material, which is mainly used for insulation and mechanical protection and does not have a sealing function.

How to properly install Dual Wall Heat Shrink Tube?

When installing double-wall heat shrink tubing, you should first select an appropriate size so that it can fit inside the component to be protected before shrinking. Then use a hot air gun to evenly heat the heat shrink tubing so that the outer layer shrinks and clings to the component, and the hot melt glue in the inner layer melts and seals the connection.

What are the precautions for using Dual Wall Heat Shrink Tube?

When using Dual Wall Heat Shrink Tube, attention should be paid to uniform heating to avoid local overheating that may cause the tube to be scorched or damaged. Additionally, choose an appropriate size and length to ensure that after shrinking, it fully covers and seals the area to be protected.

What are the common colors of Dual Wall Heat Shrink Tube?

Common colors of Dual Wall Heat Shrink Tube are black, red, and blue. Color selection is usually based on application requirements, for example, black is used for general protection.

What is the operating temperature range of the Dual Wall Heat Shrink Tube?

The operating temperature range of the Dual Wall Heat Shrink Tube is typically -45°C to 125°C, depending on the materials used. Some special materials of heat shrink tubing can withstand higher temperatures.

Is the Dual Wall Heat Shrink Tube flame retardant?

Many Dual Wall Heat Shrink Tubes are flame retardant and will self-extinguish when the fire source is removed. The quality of flame retardant properties depends on the materials used and manufacturing standards.

How to choose a suitable Dual Wall Heat Shrink Tube?

The following factors should be considered when choosing a suitable Dual Wall Heat Shrink Tube: shrinkage ratio, pipe diameter, operating temperature range, application environment (such as whether waterproofing, anti-corrosion or flame retardant is required), and color. Select the appropriate specification of double-wall heat shrink tubing based on specific application needs to ensure optimal protection.

English

English