Heat Shrink Tubing is a versatile material used across various industries for insulating, protecting, and organizing electrical connections. Among the different types available, UL (Underwriters Laboratories) heat shrink tubing stands out for its high quality and compliance with safety standards. In this guide, we will delve into the uses, applications, and best practices for utilizing UL Heat Shrink Tubing effectively.

Heat Shrink Tubing is a versatile material used across various industries for insulating, protecting, and organizing electrical connections. Among the different types available, UL (Underwriters Laboratories) heat shrink tubing stands out for its high quality and compliance with safety standards. In this guide, we will delve into the uses, applications, and best practices for utilizing UL Heat Shrink Tubing effectively.

Uses and Applications

1. Electrical Insulation: One of the primary purposes of UL heat shrink tubing is to provide electrical insulation. By enclosing wires, cables, or connectors, it protects against short circuits, abrasion, moisture, and other environmental factors. This insulation is crucial for maintaining the integrity and safety of electrical systems.

2. Strain Relief: Heat shrink tubing also serves as a strain relief mechanism, preventing mechanical stress on soldered joints or connections. By distributing tension along its length, it reduces the risk of wire breakage or detachment, particularly in applications subject to vibration or movement.

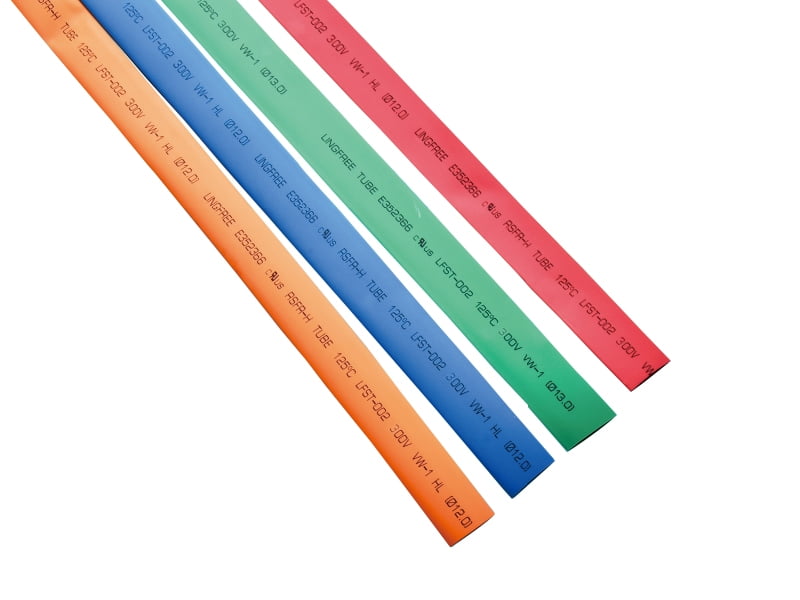

3. Cable Identification: With various colors and sizes available, UL heat shrink tubing facilitates cable identification and organization. Different colors can denote specific wires or circuits, simplifying troubleshooting, maintenance, and installation processes. Additionally, heat shrink tubing can be printed with labels or markings for further clarity.

4. Environmental Protection: In harsh or demanding environments, such as automotive, aerospace, or marine applications, UL heat shrink tubing provides an extra layer of protection. It shields components from moisture, chemicals, UV radiation, and extreme temperatures, prolonging their lifespan and reliability.

5. Splice and Joint Encapsulation: When splicing wires or creating wire joints, UL heat shrink tubing encapsulates the connection, ensuring electrical integrity and preventing exposure to external elements. This encapsulation also enhances the mechanical strength of the joint, reducing the risk of failure.

Best Practices for Using UL Heat Shrink Tubing

1. Proper Sizing: Selecting the appropriate size of heat shrink tubing is crucial for a secure and effective application. Measure the diameter of the object to be covered, ensuring that the tubing, when shrunk, fits snugly without excessive stretching or wrinkling.

2. Clean and Prepare Surfaces: Before applying heat shrink tubing, clean the surfaces thoroughly to remove any dirt, oil, or contaminants. Roughen smooth surfaces slightly to improve adhesion. Proper surface preparation ensures a strong bond and prevents air pockets or voids under the tubing.

3. Use Heat Sources Carefully: Heat shrink tubing requires controlled heat to activate the shrinking process. Common heat sources include heat guns, ovens, or even a flame (for certain types of tubing). Exercise caution to avoid overheating, which can cause damage to the tubing or underlying components.

4. Apply Heat Evenly: When shrinking the tubing, distribute heat evenly along its length to ensure uniform contraction. Move the heat source continuously, rotating the object if necessary, to prevent localized overheating and achieve a smooth, wrinkle-free finish.

5. Allow Cooling and Inspection: After shrinking, allow the tubing to cool naturally before handling or further manipulation. Inspect the finished application for any signs of damage, incomplete shrinking, or improper sealing. Address any issues promptly to maintain the integrity of the insulation.

UL heat shrink tubing is a versatile and indispensable component in electrical and mechanical applications, providing insulation, protection, and organization. By understanding its uses, applications, and best practices for installation, users can harness its benefits effectively while ensuring compliance with safety standards. Whether in automotive, aerospace, electronics, or other industries, UL heat shrink tubing offers reliable performance and peace of mind.

English

English