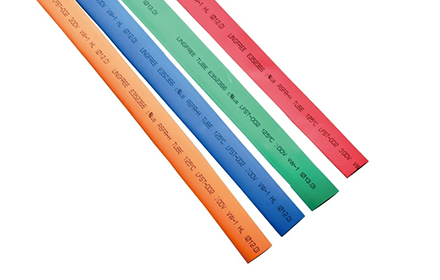

Ultra Thin Heat Shrinkable Tube is a protective and insulating material used in a wide range of electrical, electronic and communication applications. Not only does it offer the protection of traditional Heat Shrink Tubing, but it is also thinner, lighter and more flexible, providing a more efficient solution for a variety of high precision equipment and applications. In this article, we will introduce in detail the characteristics, manufacturing process, application areas and the importance of ultra-thin heat shrink tubing in modern industry.

Features of Ultra-thin Heat Shrink Tubing

1. Thin wall design

The wall thickness of ultra-thin heat shrink tubing is usually below 0.1 mm, which is much lower than that of conventional heat shrink tubing. This thin-wall design provides significant weight and space advantages for applications with stringent weight and size requirements, such as aerospace and microelectronic devices.

2. High Flexibility

Due to the special characteristics of its material and design, the ultra-thin Heat Shrinkable Tube has excellent flexibility. It can be easily wrapped around various shapes of wires, cables and electronic components to ensure that it is not easy to crack or break during use.

3. Excellent insulating properties

Ultra-thin Heat Shrinkable Tubing has good insulating properties, which can effectively prevent electrical short circuits and leakage. Its high dielectric strength allows it to maintain a stable insulation effect in high voltage environments.

4. Chemical Resistance

Ultra-thin heat shrinkable tubing is usually made of chemically resistant materials, such as polyolefins, polyvinylidene fluoride (PVDF) and so on. It can resist the erosion of many kinds of chemical substances, prolong the service life, and is suitable for harsh working environment.

5. High heat shrinkage rate

Ultra-thin heat shrinkable tubing has a high heat shrinkage rate, usually 2:1 or 3:1, i.e., it can shrink to one-half or one-third of its original diameter after heating. This allows it to wrap tightly around wires and components of different sizes, providing good protection and fixation.

Manufacturing Process for Ultra-thin Heat Shrink Tubing

The manufacturing process of ultra-thin heat shrinkable tubing includes the following steps:

1. Material selection

Ultra-thin heat shrinkable tubing is usually made of high-performance polymer materials such as polyolefin, polyvinylidene fluoride (PVDF) and polytetrafluoroethylene (PTFE). These materials have good insulation, heat and chemical resistance and can meet the needs of different applications.

2. Extrusion molding

After the material is selected, it is processed into thin-walled tubes by extrusion molding process. The wall thickness and diameter need to be strictly controlled during the extrusion molding process to ensure the uniformity and consistency of the product.

3. Irradiation cross-linking

In order to improve the mechanical strength and heat resistance of the material, irradiation cross-linking is usually performed on the extruded pipe. By irradiating the material with electron beams or gamma rays, the molecular chains of the material are cross-linked to improve its durability and stability.

4. Heating and shaping

Finally, the irradiated and cross-linked tubing is heat-shrunk by a heating and stretching process. Heating softens the material and shrinks it at a set rate, and stretching ensures that the size and shape of the tubing meets the requirements.

Applications of Ultra-thin Heat Shrinkable Tubing

Ultra-thin heat shrink tubing is widely used in various industrial fields, mainly including the following aspects:

1. Aerospace

In the aerospace industry, equipment and systems have extremely stringent weight and size requirements. Ultra-thin heat shrink tubing, with its lightweight and compact features, provides efficient insulation and protection solutions for aerospace equipment and is widely used for wrapping and fixing wires, cables and electronic components.

2. Microelectronic devices

Microelectronic devices such as smartphones, tablets and miniature sensors require high protection and insulation of components. Ultra-thin heat shrink tubing can provide reliable insulation protection without increasing the weight and volume of the device, ensuring its normal operation.

3. Medical devices

Many devices and tools in medical equipment need to be insulated and protected. The flexibility and chemical resistance of ultra-thin heat shrink tubing makes it an ideal material for electrical connections and conduit wrapping in medical devices to ensure safety and hygiene.

4. Communication equipment

Communication equipment uses a lot of ultra-thin heat shrink tubing for cable and connector insulation and protection. It can effectively prevent signal interference and electrical failures, ensuring the stability and reliability of the communication system.

5. Automotive industry

In the automotive industry, the reliability of the electrical system and electronic components directly affect the performance of the vehicle. Ultra-thin heat shrinkable tubing is used to insulate and protect automotive wire harnesses, cables and sensors, enhancing the safety and durability of the electrical system.

The importance of ultra-thin heat shrink tubing in modern industry

Ultra-thin heat shrink tubing in modern industry is of great significance, and its advantages are mainly reflected in the following aspects:

1. Improve equipment reliability

Ultra-thin heat shrink tubing can provide reliable insulation and protection for all kinds of electrical and electronic components, preventing short circuits and electrical failures, and improving the reliability and safety of equipment.

2. Saving space and weight

The thin-wall design and high flexibility of the ultra-thin heat shrink tubing can provide effective protection and insulation without increasing the size and weight of the equipment, which is suitable for space- and weight-sensitive application scenarios.

3. Reduced production costs

Ultra-thin heat shrinkable tubing is easy to process and install, which can improve production efficiency and reduce production costs. Its efficient protection performance can also reduce the frequency of maintenance and replacement of equipment, further reducing overall costs.

4. Promote technological innovation

The wide application of ultra-thin heat shrink tubing promotes technological progress and innovation in various industries. Through the continuous development and improvement of new materials and processes, ultra-thin heat shrinkable tubing shows great potential for application in more fields.

With its thin-wall design, high flexibility, excellent insulating properties and chemical resistance, ultra-thin heat shrink tubing has become an indispensable and important material in modern industry. Through precise manufacturing processes and a wide range of applications, ultra-thin heat shrink tubing provides efficient solutions for a variety of high-precision equipment and applications. With the continuous progress of science and technology, ultra-thin heat shrinkable tubing will show a broader development prospect in the future and continue to provide important support for the development of various industries.

English

English