Silicone rubber sleeving, as a versatile and protective material, has seen a significant increase in its use in several industries in recent years. Its excellent high temperature resistance, chemical resistance, flexibility and electrical insulation properties make it stand out in complex and changing environments. With the continuous progress of technology and various industries on the material performance requirements, silicone rubber casing application trends also show new features and development direction.

Environmental protection and sustainable development to promote application growth

As the global concern for environmental protection and sustainable development continues to deepen, many industries are looking for more environmentally friendly, safe materials. Silicone rubber has become an ideal choice for many application scenarios because it is non-toxic, odorless, and meets environmental standards such as RoHS and REACH. For example, in the food and beverage industry, Silicone Rubber Sleeves are widely used to protect conveyor pipes and ensure food safety and hygiene standards. In the medical industry, the biocompatibility of silicone rubber material also makes it widely used in medical devices.

Expanded applications in high-temperature environments

The performance of traditional materials in high-temperature environments tends to decline, while the high-temperature resistance of silicone rubber casing makes it a significant advantage in these areas. As temperatures in industrial manufacturing processes continue to rise, the demand for high-temperature resistant materials is also increasing. Silicone rubber casing can work stably in the range of -60 ° C to 200 ° C, so in the aerospace, automotive industry, electronics manufacturing and other areas requiring high-temperature operation, the scope of its application continues to expand.

Applications in Emerging Technologies

With the rise of 5G technology, Internet of Things (IoT), smart home and other emerging technologies, the miniaturization of materials, high performance and reliability requirements are increasingly high. With its superior electrical insulation and durability, silicone rubber casing is becoming a key component in these high-tech fields. For example, in smart home devices, Silicone Rubber Sleeves are used to protect cables and connectors, ensuring stable operation of the devices in various environments. In 5G base station equipment, silicone rubber material is widely used in various connectors and cable protection due to its durability and protective properties.

Increased demand for customization and diversified applications

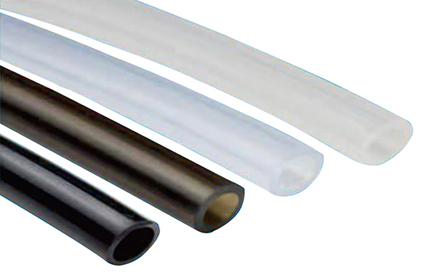

Modern industry has an increasingly high demand for product personalization, promoting the customization of silicone rubber casing. Whether in color, size, wall thickness, or in the surface treatment and logo customization, silicone rubber casing can be customized according to different application requirements. For example, in the automotive industry, different car parts may require different colors and sizes of sleeves for marking and protection. In industrial equipment, specific size and wall thickness of the silicone rubber casing can provide more accurate protection for special environments.

Chemical resistance for a wide range of applications

With the continuous development of chemical, petroleum, pharmaceutical and other industries, the demand for chemical-resistant materials is increasing. Silicone rubber casing has gradually become an important material for these industries due to its good resistance to acids, alkalis, solvents and other chemicals. In particular, the application of silicone rubber casing is growing rapidly in the protection of piping in chemical equipment, sealing and protection of storage tanks, and piping systems in pharmaceutical equipment.

The trend in the application of silicone rubber casing is characterized by diversification and technologization. From the drive for environmental protection and sustainability, to the expansion of demand in high-temperature environments, to innovative applications in emerging technology areas, silicone rubber casing is meeting the challenges of the future with its outstanding performance and wide range of adaptability. With the continuous improvement of material performance requirements in various industries, the application prospect of silicone rubber casing will be even broader, and its position in the global industry will be even more important.

English

English