Marine environments present one of the harshest conditions for electrical components. From saltwater and humidity to UV radiation and extreme temperatures, cables and wires in boats, ships, and offshore platforms are constantly exposed to potential damage. In these conditions, it’s crucial to use materials that can protect sensitive components and ensure their longevity. Adhesive Lined Heat Shrink Tubing has become a go-to solution for enhancing the durability of electrical systems in marine applications. In this article, we’ll explore how this versatile product protects electrical components, prevents water ingress, and extends the life of cables and wiring in marine environments.

The Challenges of Marine Environments

Marine environments expose electrical systems to several damaging factors, including:

1.Saltwater Exposure: Saltwater is highly corrosive and can rapidly degrade unprotected metal components, leading to electrical faults and component failure.

2.Moisture and Humidity: Moisture can seep into connectors and wires, causing corrosion and short circuits.

3.UV Radiation: Prolonged exposure to sunlight can cause degradation of plastics and rubber, weakening the insulation of cables and causing them to crack or break.

4.Extreme Temperatures: Marine environments are subject to temperature fluctuations, which can cause materials to expand and contract, weakening their structural integrity over time.

To combat these challenges, Adhesive Lined Heat Shrink Tubing provides a comprehensive solution by offering both mechanical protection and environmental sealing for cables, connectors, and other electrical components.

How Adhesive Lined Heat Shrink Tubing Works

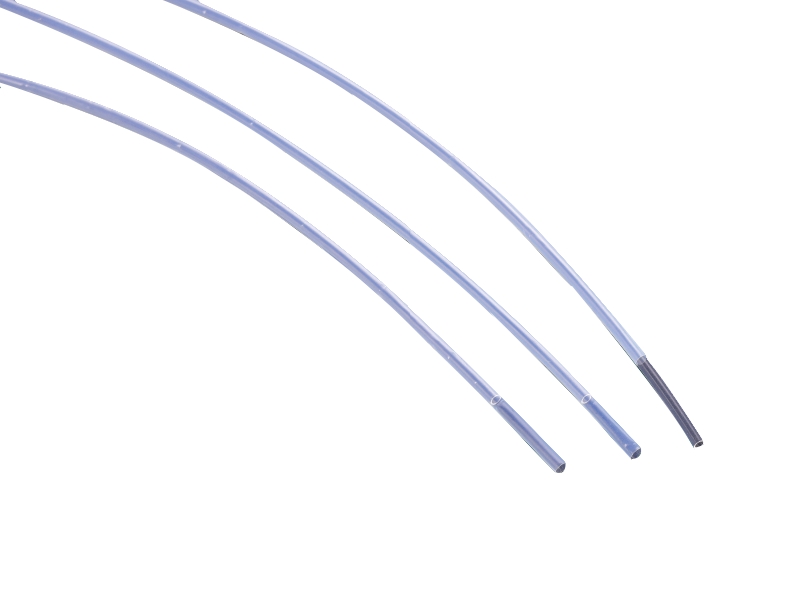

Adhesive Lined Heat Shrink Tubing is a dual-layer tubing that combines the benefits of heat shrink with an adhesive lining. The outer layer is typically made from a durable polymer, such as polyolefin, that shrinks when exposed to heat. The inner layer consists of an adhesive that melts when heated, bonding tightly to the component it covers. This adhesive layer forms a strong, waterproof seal that prevents moisture, saltwater, and other contaminants from entering the tubing, protecting the electrical connections inside.

For marine applications, this dual-wall construction is especially beneficial. The heat-shrinkable outer layer provides a tight, flexible fit around wires, while the adhesive lining offers an additional layer of protection, ensuring a long-lasting seal that resists environmental stress.

Protecting Against Corrosion with Adhesive Lined Heat Shrink Tubing

One of the biggest threats to electrical systems in marine environments is corrosion. When saltwater comes into contact with exposed metal parts, it accelerates the oxidation process, leading to rust and eventual failure of the components. Adhesive Lined Heat Shrink Tubing helps prevent corrosion by creating a secure, moisture-resistant seal around wires and connectors.

The adhesive inside the tubing bonds tightly to the surface of the component, ensuring that water or saltwater cannot penetrate. This effectively isolates electrical connections from the corrosive effects of the marine environment, extending the life of cables and connectors.

Preventing Water Ingress

Water ingress is another major concern in marine applications. Even small amounts of moisture can cause significant damage to electrical components, leading to short circuits and equipment failure. Heat Shrink Tubing With Adhesive provides a waterproof barrier that prevents water from entering electrical systems.

When the tubing is heated, the adhesive lining melts and flows into any gaps or crevices, filling them completely. This creates a watertight seal that keeps out moisture, ensuring that the electrical components remain dry and functional even in the most demanding marine conditions.

UV Protection and Durability

Exposure to UV radiation from the sun can degrade plastics and rubber over time, leading to brittleness, cracking, and loss of insulation properties. Adhesive Heat Shrink products, particularly Dual Wall Adhesive Heat Shrink Tubing, are designed to withstand UV exposure, making them ideal for outdoor and marine use.

The outer layer of the tubing is often made from UV-resistant materials that prevent the tubing from becoming brittle or discolored when exposed to sunlight. This ensures that the protective properties of the tubing remain intact, even after prolonged exposure to harsh UV rays.

Heat Shrink with Glue for Seamless Protection

The combination of Heat Shrink with Glue offers a seamless solution for protecting marine electrical systems. When heat is applied to the tubing, the outer layer shrinks, while the inner adhesive melts and bonds securely to the component. This process ensures that there are no gaps or weak points in the seal, providing optimal protection against water, salt, and UV radiation.

Applications in Marine Environments

Dual Wall Heat Shrink Tubing and other adhesive-lined heat shrink products are used extensively in marine environments for a wide range of applications:

1.Boat Wiring: Protecting cables and wires from saltwater, moisture, and UV damage.

2.Marine Connectors: Sealing connectors to prevent water ingress and corrosion.

3.Offshore Platforms: Ensuring electrical systems remain intact in harsh, offshore conditions.

4.Underwater Equipment: Protecting electrical components in submerged or partially submerged conditions.

Adhesive Lined Heat Shrink Tubing provides a reliable, durable solution for protecting electrical components in marine environments. Whether it’s safeguarding against corrosion, preventing water ingress, or offering UV protection, this product ensures that cables and connectors remain safe and functional even in the harshest conditions. With its dual-wall construction and heat-activated adhesive, it offers the ultimate protection for electrical systems in boats, ships, and offshore platforms, extending the life of marine equipment and ensuring reliable performance in demanding environments.

English

English