In the modern electrical industry, especially in high-voltage environments such as transformers, switchgear, and power distribution systems, insulation and protection are crucial for system reliability and operator safety. Among various insulation solutions, PTFE (Polytetrafluoroethylene) heat shrink tubing stands out as a premium option due to its exceptional thermal, chemical, and electrical resistance properties. This article explores the vital role of PTFE heat shrink tubing in high-voltage electrical systems and why it is increasingly preferred in mission-critical installations.

What Is PTFE Heat Shrink Tubing?

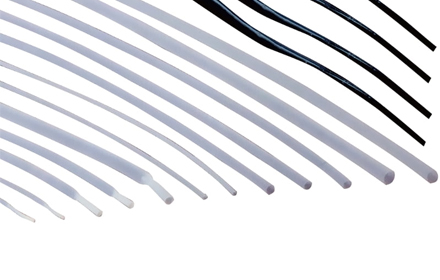

PTFE Heat Shrinkable Tubing is a specialized type of insulating material made from polytetrafluoroethylene. When exposed to heat—typically around 350°C—it shrinks to form a tight, protective layer over cables, terminals, and connections. Unlike conventional shrink tubing, PTFE offers superior resistance to extreme temperatures (from -65°C to +260°C), aggressive chemicals, and electrical stress.

PTFE Tubing used in industrial and high-voltage settings often complies with SAE-AMS-DTL-23053/13 military standard, ensuring high performance even in demanding applications.

Challenges in High-Voltage Environments

High-voltage systems are often subjected to:

Thermal stress from current load or ambient temperature

Chemical exposure in industrial or outdoor environments

Electrical surges or corona discharge

Physical wear and vibration

Traditional insulation materials may degrade under such conditions, leading to electrical failures, insulation breakdown, or even fire hazards. PTFE heat shrink tubing addresses these challenges through its unique set of properties.

Why PTFE Heat Shrink Tubing Excels in High-Voltage Applications

1. Superior Electrical Insulation

PTFE has an excellent dielectric strength (typically above 60 kV/mm), making it ideal for insulating live components in high-voltage assemblies. It helps prevent arc-over, corona discharge, and power losses, especially in tight spaces or complex wiring environments.

2. Exceptional Temperature Resistance

With a continuous working temperature of up to 260°C, Ptfe Tubing resists degradation under the heat generated by high-voltage currents or during thermal cycling. It remains stable and does not melt or char, unlike PVC or polyethylene-based tubing.

3. Chemical and Oil Resistance

In power stations, substations, and industrial environments, cables and connections are often exposed to oils, coolants, and corrosive vapors. PTFE Tubing remains unaffected by almost all chemicals, ensuring long-term protection and reducing maintenance frequency.

4. Flame Retardant and Non-Toxic

PTFE is naturally flame retardant and does not release toxic gases when exposed to high heat, making it safer for confined or populated environments.

5. Shrink Ratios for Versatility

PTFE heat shrink tubing is available in 1.7:1 and 4:1 shrink ratios, which allows it to conform tightly to irregular shapes, lugs, and connectors. This flexibility ensures full coverage and eliminates air gaps, which could otherwise lead to tracking or dielectric failure.

Application Scenarios in the Electrical Industry

● Transformer Lead Protection

PTFE tubing is applied over transformer leads to prevent arc flash and insulate high-current connections.

● Busbar and Terminal Insulation

In high-voltage switchgear, it is used to insulate and protect busbars, reducing the risk of short circuits and surface discharge.

● Motor Windings and Coil Terminations

For industrial motors and generators, PTFE tubing is used at coil ends and windings, which are exposed to high thermal and mechanical stress.

● Cable Splicing and Joint Sealing

When connecting or splicing high-voltage cables, PTFE heat shrink tubing provides a reliable sealing and insulation barrier, ensuring longevity and operational safety.

● Sensor and Instrument Protection

For power monitoring equipment and sensors located within high-voltage environments, PTFE tubing ensures insulation from stray voltages and EMI (electromagnetic interference).

Compliance and Standards

PTFE heat shrink tubing for high-voltage systems often adheres to stringent electrical and environmental standards, including:

RoHS compliance

UL 224

SAE-AMS-DTL-23053/13

IEC and IEEE insulation standards

These certifications guarantee consistent performance, safety, and compatibility across international markets.

As power systems grow more complex and demanding, the importance of reliable insulation becomes critical. PTFE heat shrink tubing is an advanced, high-performance solution that meets and exceeds the insulation needs of high-voltage electrical systems. Whether used in transformers, switchgear, or high-energy equipment, its unmatched combination of electrical strength, thermal endurance, and chemical resistance ensures long-term reliability and safety.

For engineers, installers, and manufacturers aiming to elevate their insulation standards in harsh or sensitive environments, PTFE heat shrink tubing is not just an option—it’s a necessity.

English

English