PVDF (Polyvinylidene Fluoride) Heat Shrinkable Tubing is a type of plastic tubing known for its high resistance to heat, chemicals, and abrasion. It's often used for applications requiring high purity and excellent chemical resistance, such as in the aerospace, automotive, electrical, and chemical processing industries. Here are some key features and benefits of PVDF Heat Shrinkable Tubing:

Usage

Semi hard, transparent,flame retardant, long-term use at 175 ℃,wear-resistant.

Shrinkage ratio: 2:1

Operating temperature:-55 ℃~175 ℃Withstand voltage level: 60ov

Operating temperature:-55 ℃~175 ℃CWithstand voltage level: 60ov

Environmental protection standard:RoHS compliant

Environmental protection standard:RoHS compliant Color: transparent (normal)

Chemical Resistance: PVDF tubing is resistant to a wide range of chemicals, including solvents, acids, and bases, making it suitable for harsh environments.

High Temperature Resistance: It can withstand high temperatures, typically up to around 150°C (302°F), and has a high melting point.

Flame Retardant: PVDF is inherently flame retardant and has low smoke generation when exposed to fire.

Mechanical Strength: It has good mechanical properties, including high tensile strength and abrasion resistance.

Electrical Insulation: PVDF tubing provides excellent electrical insulation, which is essential for many electrical and electronic applications.

UV Resistance: It is resistant to ultraviolet (UV) light, making it suitable for outdoor applications.

Low Outgassing: PVDF has low levels of outgassing, which is important in applications like aerospace or clean rooms where contamination needs to be minimized.

Applications

Electrical and Electronic: Used for insulating wires and protecting electrical connections from heat and chemical exposure.

Automotive: Applied in wire harnesses and protection of automotive components.

Aerospace: Used for protecting sensitive components from harsh environmental conditions.

Chemical Processing: Employed in environments with exposure to aggressive chemicals.

Medical: Used in medical devices and equipment requiring sterilization.

Installation

Preparation: Measure and cut the required length of tubing.

Placement: Place the tubing over the object or wire that needs protection.

Heating: Use a heat gun or another heat source to evenly shrink the tubing around the object. Ensure even heating to avoid uneven shrinkage or damage.

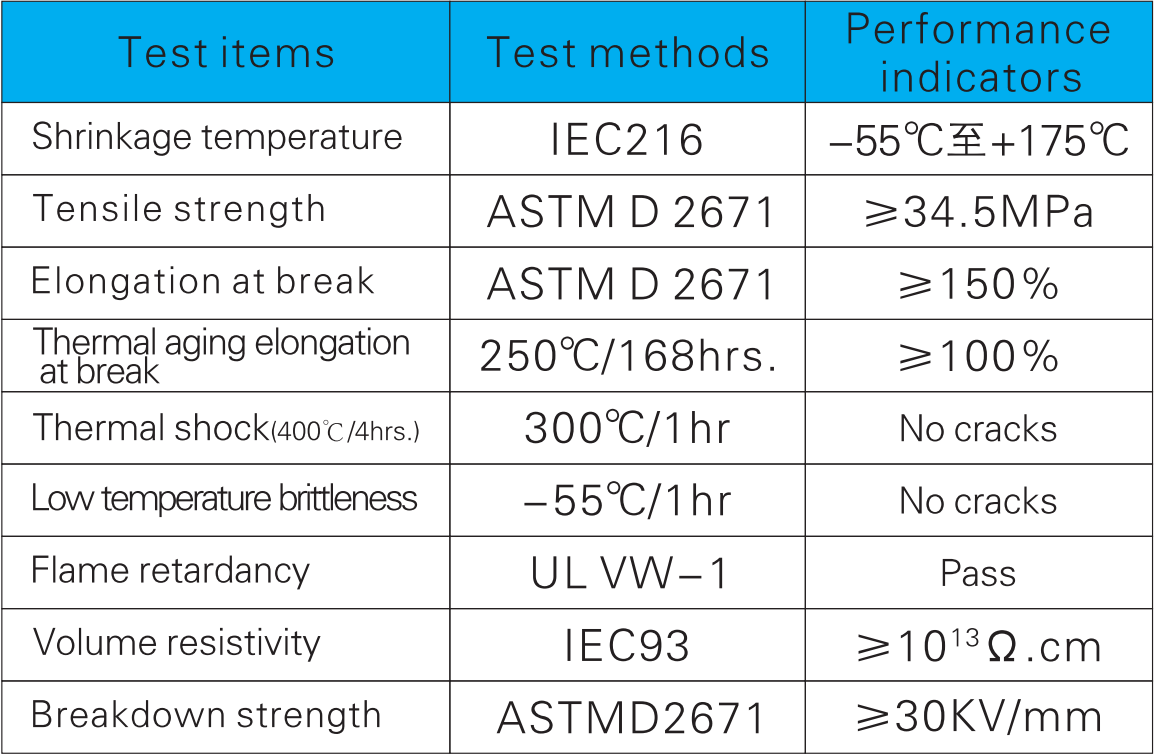

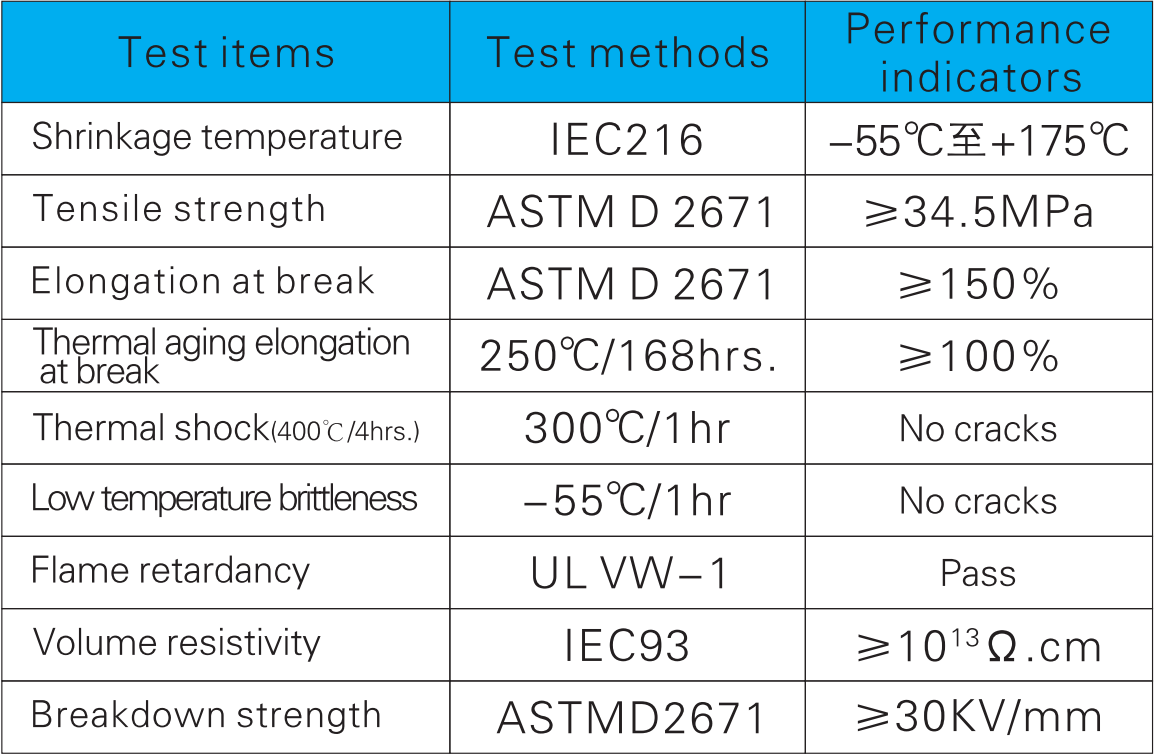

Characteristics

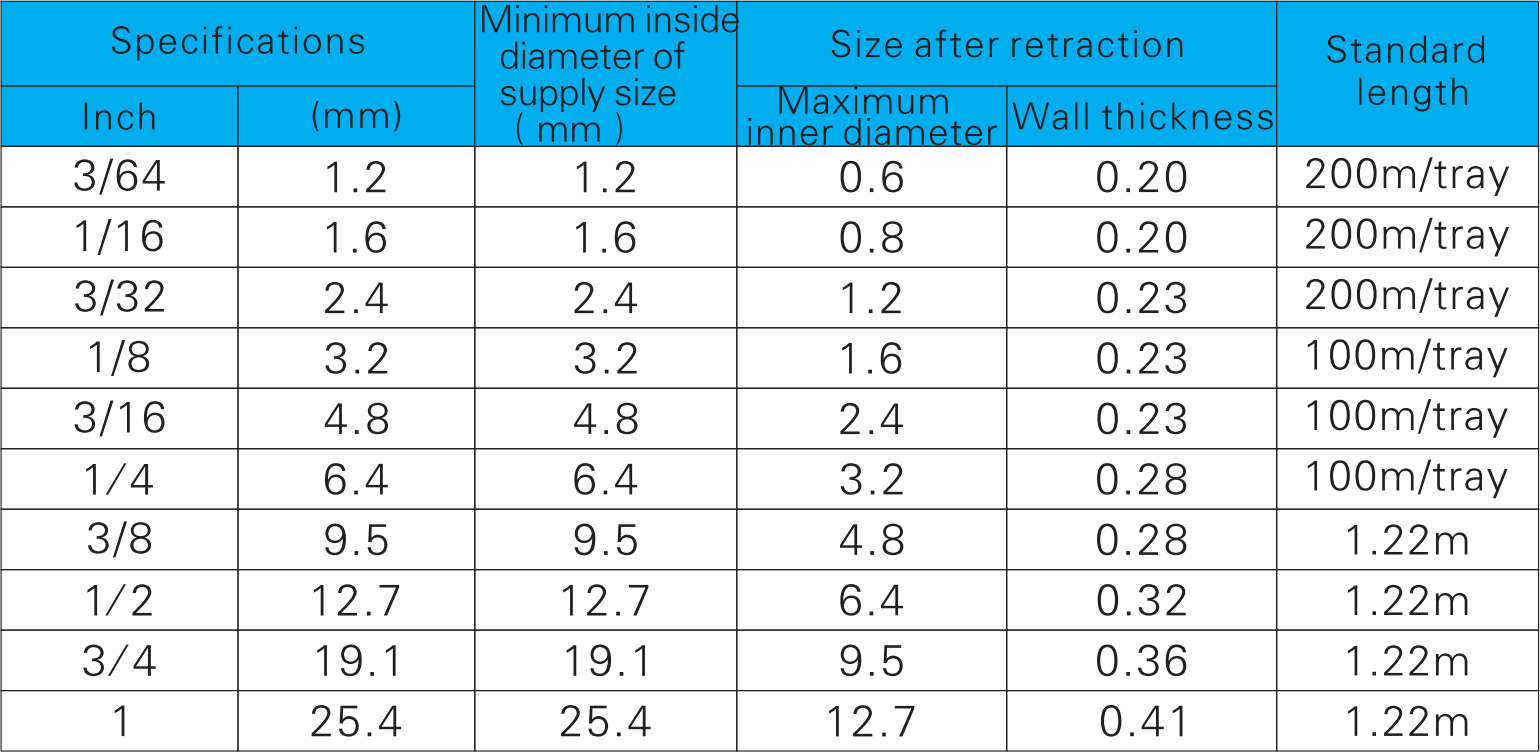

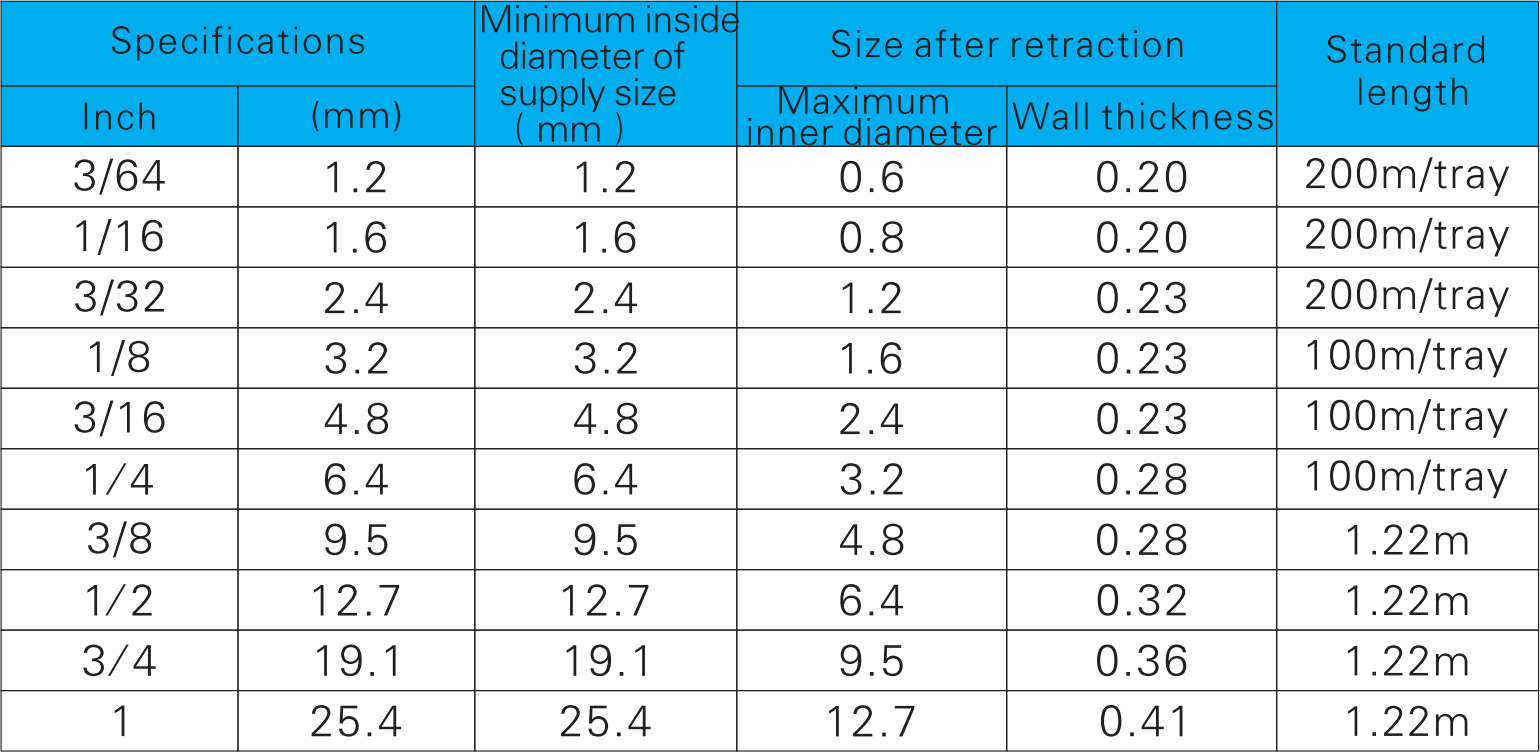

Dimension

FAQ:

What material is PVDF Heat Shrinkable Tubing made of?

PVDF Heat Shrinkable Tubing is made of polyvinylidene fluoride.

What is the main purpose of PVDF Heat Shrinkable Tubing?

PVDF Heat Shrinkable Tubing is mainly used in electrical and electronic, petrochemical and smelting industries to provide insulation, protection and reinforcement for wires, cables and electronic components.

What is the high temperature resistance of PVDF Heat Shrinkable Tubing?

PVDF Heat Shrinkable Tubing has excellent high temperature resistance, with an operating temperature range of -55°C to 175°C, a minimum shrinkage temperature of 155°C, and a minimum full shrinkage temperature of 175°C. The temperature range of PVDF Heat Shrinkable Tubing is -55°C to 175°C, with a minimum shrinkage temperature of 155°C.

How does PVDF Heat Shrinkable Tubing shrink?

PVDF Heat Shrinkable Tubing shrinks by heat, usually using a heat gun or heat shrink machine to heat the tubing to a certain temperature, it will automatically shrink and wrap tightly around the protected object.

What is the shrinkage ratio of PVDF Heat Shrinkable Tubing?

PVDF Heat Shrinkable Tubing typically has a shrinkage ratio of 2:1, which means that when the tubing is heated and shrunk, its diameter is reduced to half of its original diameter.

What are the chemical properties of PVDF Heat Shrinkable Tubing?

PVDF Heat Shrinkable Tubing has excellent chemical resistance and is able to resist corrosion at room temperature from chemicals such as acids, alkalis, strong oxidizers and halogens.

What are the advantages of PVDF Heat Shrinkable Tubing over other heat shrink materials?

PVDF Heat Shrinkable Tubing has higher mechanical strength, abrasion resistance, weatherability and self-lubricating properties than other heat shrink materials.

What are the key steps in the production process of PVDF Heat Shrinkable Tubing?

The manufacturing process for PVDF Heat Shrinkable Tubing includes the key steps of compounding, extrusion, irradiation, expansion and packaging, with irradiation cross-linking being an important part of the manufacturing process to improve the properties of the tubing.

How flame retardant is PVDF Heat Shrinkable Tubing?

PVDF Heat Shrinkable Tubing is highly flame retardant, which reduces the risk of fire spreading in extreme situations such as fires.

What should I pay attention to when using PVDF Heat Shrinkable Tubing?

When using PVDF Heat Shrinkable Tubing, care needs to be taken with the heating temperature and heating time to ensure that the tubing shrinks sufficiently and wraps tightly around the object to be protected. At the same time, care needs to be taken to avoid overheating, which could damage the protected object or the tubing itself.

English

English