Fiberglass sleeving is an insulating protection tubing made from high-density woven fiberglass, specially treated for enhanced performance. It offers excellent heat resistance, electrical insulation, and chemical corrosion resistance. It is widely used in industries like motors, cables, transformers, and more, providing superior insulation and mechanical protection for various applications.

Structure

Atice: ltis made byimmersing in silicon resin and coating the outerlayer with a layer of silicon image glue.Because it contains two layersof silica gel and glass fiber,it has excellentinsulation and cushionresistance effects and good winding performance. Flame retardantself extinguishing ULvw-1 and dielectric NEMAH&H standards.

Temperature resistance:(-30℃~200 ℃)

Withstand voltage:1.2KV,1.5KV,2.5KV, 4.0KV and 7.0KV.

Characteristics:

Heat Resistance: Fiberglass sleeving is known for its excellent heat resistance. It can withstand high temperatures, typically ranging from around -30°C to 200°C .

Electrical Insulation: It provides good electrical insulation properties, making it suitable for applications where electrical components need protection from heat and abrasion.

Abrasion Resistance: Fiberglass sleeving is highly resistant to abrasion, making it suitable for use in rugged environments where mechanical wear and tear are concerns.

Chemical Resistance: It is generally resistant to many chemicals, oils, and solvents, which adds to its durability and suitability for various industrial applications.

Flexibility: Despite being durable and resistant, fiberglass sleeving remains flexible, allowing for easy installation and manipulation around wires, cables, or hoses.

Lightweight: Fiberglass sleeving is lightweight compared to alternatives like metal or ceramic sleeves, which makes it easier to handle and install.

UV Resistance: Some types of fiberglass sleeving are UV resistant, which means they can withstand prolonged exposure to sunlight without deteriorating or losing their properties.

Flame Retardant: Many fiberglass sleeving products are inherently flame retardant, providing an added layer of safety in applications where fire hazards are a concern.

Non-Conductive: Fiberglass is non-conductive, which makes it suitable for insulating and protecting electrical components from short circuits or other electrical hazards.

Variety of Sizes and Grades: Fiberglass sleeving comes in various sizes, thicknesses, and grades to suit different applications and requirements, offering flexibility in design and usage.

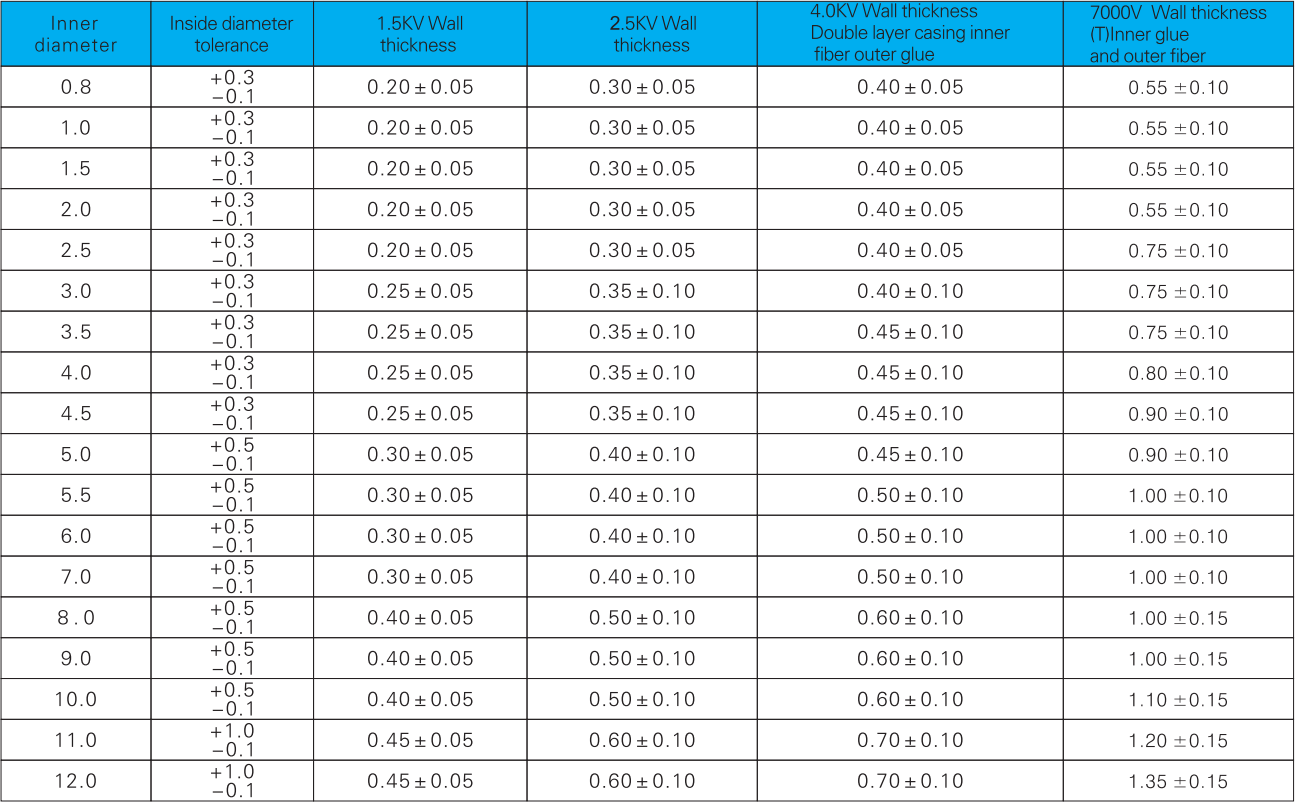

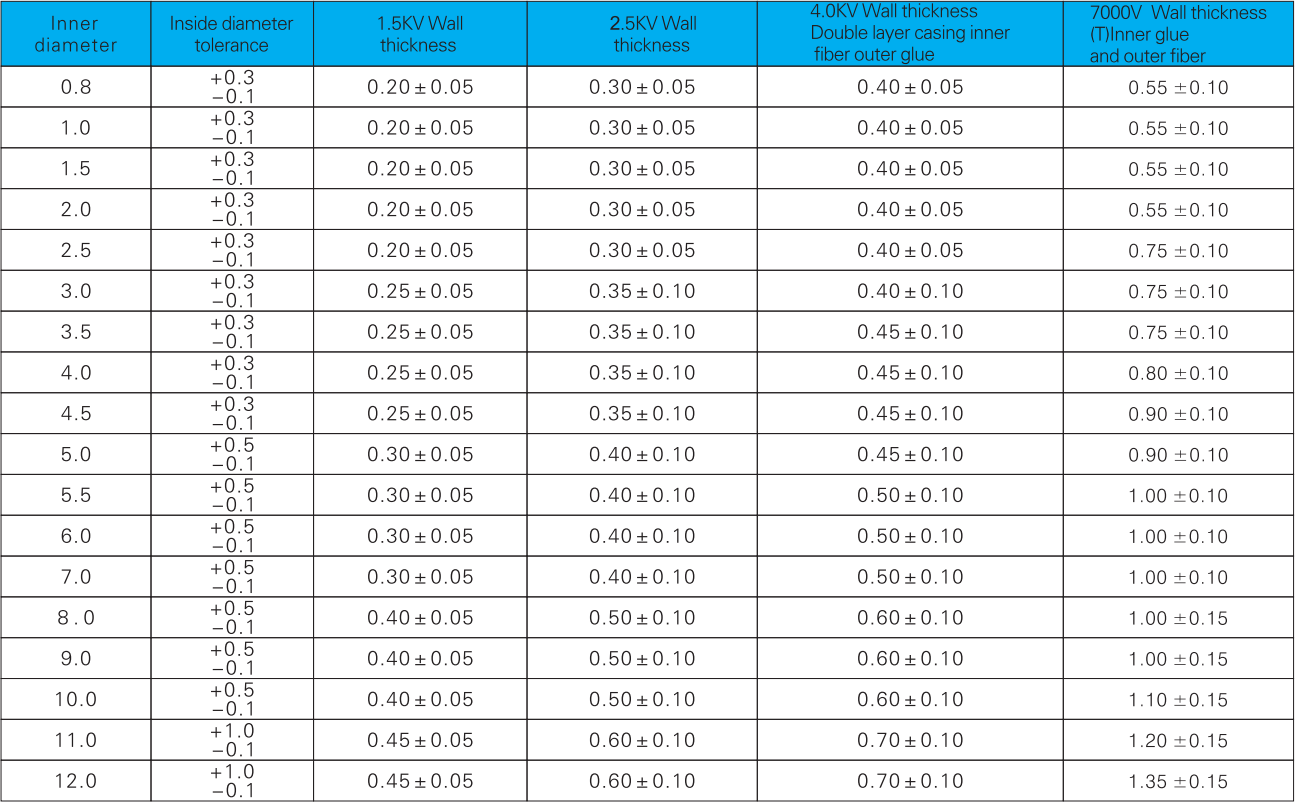

Dimension table1

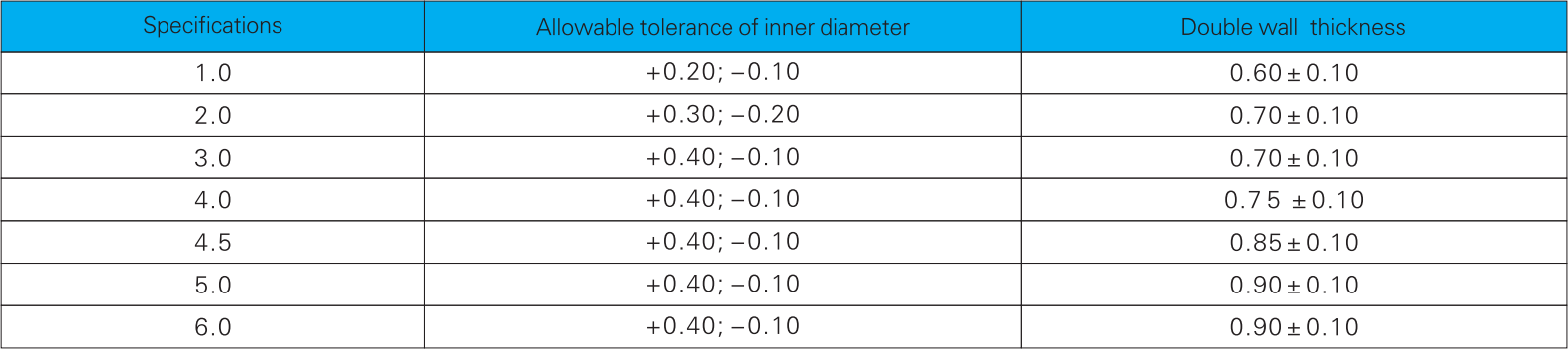

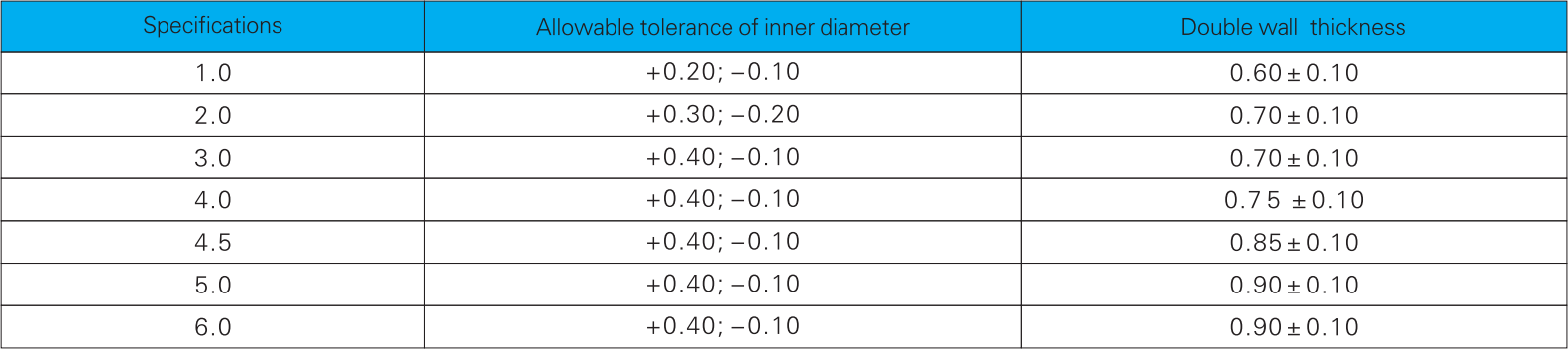

Dimension table2(Inside rubber outside fiber 7.0kv)

Product Features (Advantages)

Excellent Temperature Resistance: Can withstand temperatures up to 200°C or even higher, making it suitable for high-temperature environments.

Superior Electrical Insulation: With high dielectric strength, it effectively prevents electrical leakage, ensuring the safe operation of equipment.

Chemical Corrosion Resistance: Resistant to oils, solvents, acids, and alkalis, making it ideal for harsh environments.

High Strength and Flexibility: The fiberglass material offers exceptional wear resistance and tensile strength, making it easy to install and use.

Outstanding Flame Resistance: Meets UL 1441 and IEC standards, providing safety and preventing fire hazards.

Customizable Specifications: Available in different diameters, wall thicknesses, and colors, with options for customized orders.

Applications (Use Cases - Industry Applications)

Motor and Transformer Industry: Used for insulation and protection of motor coils and cable connectors, enhancing equipment safety.

Electronics Protection: Ideal for capacitors, inductors, PCB boards, and other components, providing electrical insulation and mechanical protection.

Aerospace and Military Applications: Used in spacecraft and electrical control systems, ensuring stable operation in high-temperature and high-pressure environments.

Renewable Energy: Applied in electric vehicle (EV) battery packs and power systems, protecting electrical lines.

Home Appliances and Industrial Equipment: Used for electrical wire protection in microwaves, heating elements, and industrial heating equipment, extending service life.

Frequently Asked Questions (FAQ)

Q1: Does the fiberglass sleeving support custom specifications?

Yes, we offer customizable options for size, color, and insulation grade to meet specific customer requirements.

Q2: What is the temperature range for this product?

Our fiberglass sleeving typically supports a temperature range from -60°C to 200°C, with some models capable of withstanding higher temperatures.

Q3: Is the fiberglass sleeving environmentally friendly?

Yes, our products meet RoHS, REACH, and other environmental standards, making them non-toxic and safe for use.

Q4: Does the product have flame-resistant properties?

Yes, our fiberglass sleeving has excellent flame resistance and complies with UL certification standards.

Company Brand Introduction

As a leading supplier of fiberglass insulation materials, we specialize in developing high-performance insulation protection products. Our company has advanced manufacturing processes and a rigorous quality control system, with products certified by UL, CE, RoHS, and other international standards. We export our products to various countries and regions around the world and provide professional customization services to ensure superior performance in all types of applications.

English

English