As a leading Silicone Rubber Sleeve Supplier, we offer a wide range of high-quality Silicone Rubber Sleeves designed to provide exceptional protection and performance in various industries. Our Silicone Rubber Sleeve products are known for their flexibility, high temperature resistance, and outstanding electrical insulation properties, making them perfect for both industrial and consumer applications.

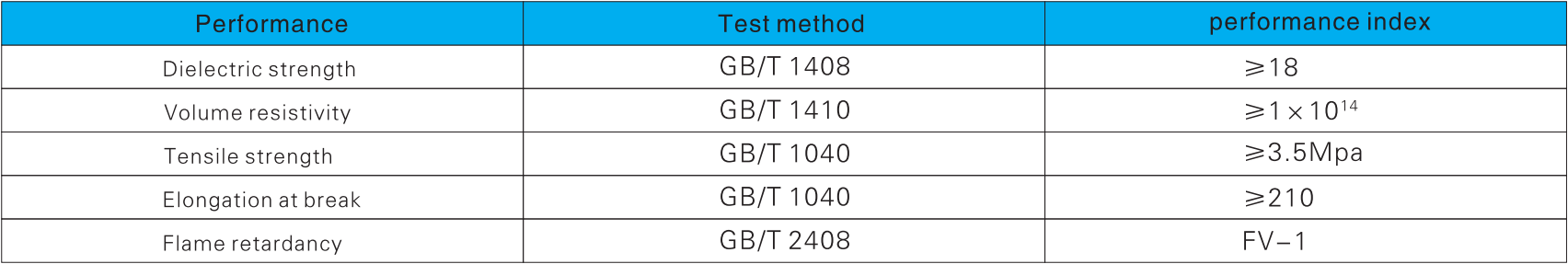

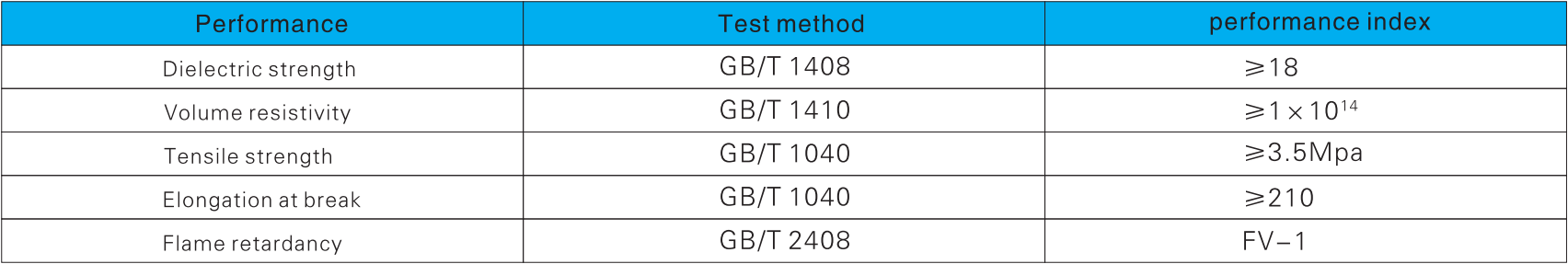

Characteristic

Continuoususetemperature:-60℃℃~200 ℃;

Soft, arc resistant and corona resistant;

The product complies with EU RoHS directiveand has foodcertification;

Various specifications can be customized according tocustomerrequirements.

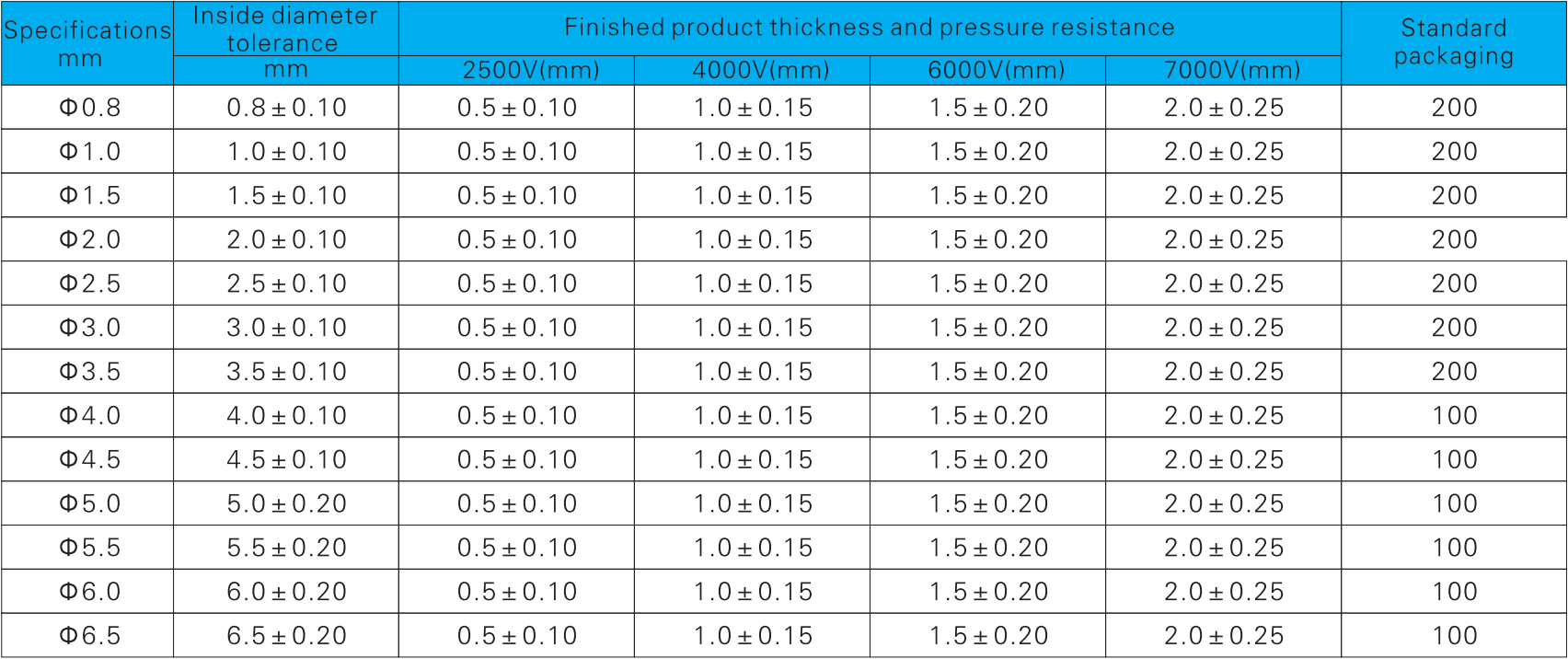

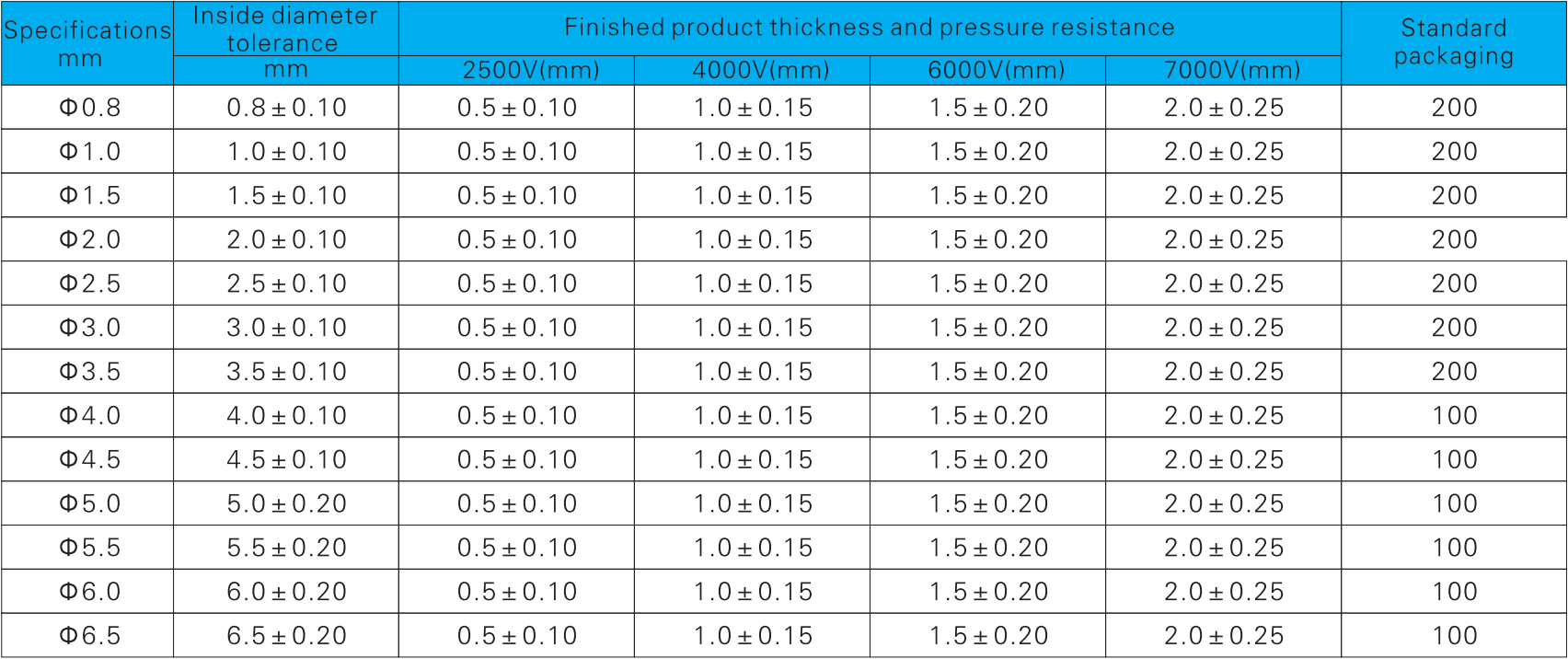

Specification

Dimension

Key Features and Benefits

Our Silicone Rubber Sleeve products are engineered from high-grade silicone, ensuring superior durability and performance under demanding conditions. Whether you're looking for a Silicone Rubber Sleeve Tube for insulation or protection, or a Silicone Insulation Sleeve for electrical components, our products meet rigorous standards.

High Temperature Silicone Sleeve: Ideal for environments subject to extreme heat, these sleeves provide long-lasting performance in temperatures ranging from -60°C to 200°C or higher.

Waterproof Silicone Sleeve: Our silicone sleeves offer reliable waterproof protection, ensuring that components are safeguarded from moisture and environmental damage.

Rubber Silicone Sleeve: Combining flexibility with durability, our rubber silicone sleeves offer robust protection for cables, wiring, and other critical components.

Silicone Sleeve for Electrical Wiring: Perfect for insulating electrical wires and preventing short circuits, our silicone sleeves ensure safety and protection for wiring systems.

Silicone Sleeve for Cable Protection: Designed to safeguard cables from abrasion, heat, and chemicals, our silicone sleeves extend the lifespan of your cables and reduce the risk of damage.

Applications

Our Silicone Rubber Sleeves are suitable for a variety of applications across different industries:

Electrical & Electronics: For insulation and protection of wires, connectors, and other electrical components.

Automotive: Ideal for protecting wires and cables in vehicles from heat, moisture, and wear.

Medical Devices: Used for medical-grade applications requiring flexibility, safety, and biocompatibility.

Industrial: Effective in high-temperature environments and for safeguarding critical equipment and wiring systems.

Why Choose Us?

As a trusted Silicone Rubber Sleeve Supplier, we pride ourselves on providing high-quality, durable, and cost-effective solutions for a wide range of industries. Whether you need a Silicone Rubber Sleeve Tube or a custom Silicone Insulation Sleeve, we have the expertise and products to meet your needs. Our products are built to withstand extreme conditions, ensuring reliability and long-term protection for your applications.

Specifications and Customization Services

Silicone Rubber Sleeving is available in a wide range of specifications and sizes to meet the needs of different applications. Sleeving can be customized in different colors, sizes, and wall thicknesses to suit specific usage environments. Customization services include laser marking, printed logos, and special shapes to ensure a perfect fit for a particular application.

FAQ

What is silicone rubber sleeving and what is it mainly made of?

Silicone Rubber Sleeving is a protective sleeving made of high performance silicone material, which is mainly used to protect cables, pipes and other components from external environmental damage.

What is the operating temperature range of silicone rubber sleeving?

Silicone rubber sleeving can typically withstand temperatures ranging from -60°C to 200°C, making it suitable for extreme high and low temperatures.

What are the main applications for silicone rubber sleeving?

The main areas of application include cable protection in electrical and electronic equipment, pipe insulation, protection of wires and pipes in the automotive industry, protection of conduits in medical equipment and protection of components in industrial equipment.

What are the electrical insulation properties of silicone rubber sleeving?

Silicone rubber has excellent electrical insulation properties, providing reliable insulation for cables and wires against short circuits and leakage.

Is silicone rubber sleeving chemically resistant?

Yes, silicone rubber has good resistance to acids, alkalis, and a wide range of organic solvents, making it effective in protecting internal components in corrosive chemical environments.

How flexible is silicone rubber sleeving and is it easy to handle during installation?

Silicone rubber sleeving has excellent flexibility and elasticity, and is not easily deformed, so it can be easily installed on various shapes of components and is suitable for complex installation environments.

Is silicone rubber tubing suitable for outdoor use?

It is suitable for outdoor use. Silicone rubber is resistant to aging and UV rays, and will not easily age or degrade when used in outdoor conditions, ensuring its long life.

Is silicone rubber tubing environmentally friendly and does it meet the relevant safety standards?

Yes, Silicone Rubber Sleeving is free of hazardous substances and complies with environmental and safety standards such as RoHS and REACH, making it an environmentally friendly and non-toxic material.

What is the main role of silicone rubber bushings in the automotive industry?

In the automotive industry, silicone rubber sleeving is mainly used to protect wires and pipes in the engine compartment from heat, abrasion and chemicals, ensuring the reliability and safety of automotive components.

Is it possible to customize different colors and sizes of silicone rubber sleeves?

Yes, it is possible. Silicone Rubber Sleeving can be customized with different colors, sizes and wall thicknesses according to customer's needs, and additional customization services such as laser marking and printing logos can be provided to meet the requirements of special applications.

English

English