UL heat shrink tubing is an important electrical insulation material that plays a key role in multiple industries. Its application range covers wire connection, wire end treatment, solder joint protection, wire harness marking, resistance and capacitor insulation protection, and corrosion protection of metal rods or tubes.

UL heat shrink tubing is an important electrical insulation material that plays a key role in multiple industries. Its application range covers wire connection, wire end treatment, solder joint protection, wire harness marking, resistance and capacitor insulation protection, and corrosion protection of metal rods or tubes.

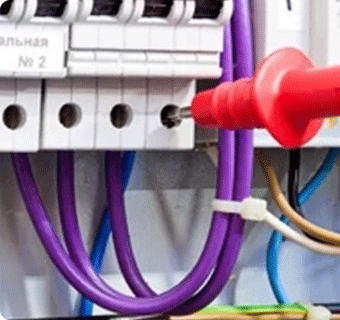

1. Wire connection

UL heat shrink tubing plays an important role in wire connections. It can be used to connect the ends of wires and insulated cables, protecting the connection points from mechanical damage, chemical corrosion and the influence of the external environment. By placing UL heat shrink tubing at the connection site, you can ensure a strong connection and good insulation, thereby improving the safety and reliability of your electrical system.

2. Line end processing

In electrical engineering, wire end processing is very important and directly affects the stability and reliability of the electrical system. UL heat shrink tubing can be used for wire end treatment to insulate and protect exposed wire ends to prevent short circuits and electrical faults. At the same time, it can also provide additional mechanical protection and extend the service life of the wire.

3. Solder joint protection

Solder joints are important components in the circuit and need to be effectively protected. UL heat shrink tubing can be used to protect solder joints from mechanical damage, corrosion and the impact of the external environment. By covering the UL heat shrink sleeve, the durability and stability of the solder joints can be effectively improved.

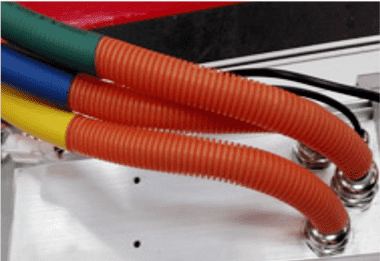

4. Harness marking

In complex electrical systems, it is very important to label the wiring harness. UL heat shrink tubing has good printability, and logo text or patterns can be printed on the tubing to mark different wire harnesses, cables or connection points. This can improve the maintenance efficiency of the electrical system and reduce the difficulty of troubleshooting.

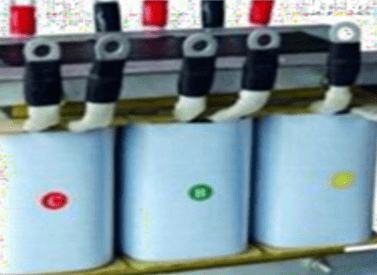

5. Resistor and capacitor insulation protection

In electronic circuits, components such as resistors and capacitors need to be well protected by insulation. UL heat shrink tubing can be used to insulate and encapsulate resistors and capacitors to prevent them from being disturbed and affected by the external environment. This helps ensure the stability and reliability of electronic circuits.

6. Corrosion protection of metal rods or tubes

Metal rods or tubes often require corrosion protection to extend their service life. UL heat shrink tubing has good corrosion resistance and can be used to cover the surface of metal rods or tubes to protect them from chemical corrosion and oxidation. This helps protect the quality and performance of metal materials.

As a multi-functional electrical insulation material, UL heat shrink tubing has been widely used in electronics, electrical, automotive, aerospace and other industries. It can not only be used for basic functions such as wire connection, wire end treatment, solder joint protection, and wire harness marking, but can also be used for special applications such as resistance and capacitor insulation protection and corrosion protection of metal rods or tubes. With the continuous advancement of science and technology and the continuous development of industry, the application scope of UL heat shrinkable sleeves will continue to expand, providing more possibilities for the development and progress of all walks of life.

English

English