The UL Heat Shrinkable Sleeve is a highly durable and versatile solution for insulating and protecting electrical wires, cables, and connectors. Certified by UL (Underwriters Laboratories), this Heat Shrinkable Sleeve is designed to offer exceptional protection in industrial, automotive, and consumer electronics applications. When exposed to heat, it shrinks uniformly, creating a tight, secure fit around the components it covers, ensuring long-lasting insulation, abrasion resistance, and environmental protection.

Principles and uses of UL heat shrink tubing:

UL halogen-free environmentally friendly flame-retardant Heat Shrinkable Sleeves are made of high-quality polymers, which are scientifically proportioned and mechanically blended into polymer alloys. After the product is formed, it is cross-linked by electron accelerator radiation and continuously expanded. Its products have the advantages of softness, flame retardancy, fast shrinkage, and stable performance. It is widely used in wire connection, solder joint protection, wire ends, wire harnesses, electronic device protection and insulation treatment: fitness equipment parts and steel structure surface protection; anti-rust and anti-corrosion treatment of related products; marking of wires and other products, etc.

Key Features:

UL Certification: The UL Heat Shrinkable Sleeve is UL-listed, ensuring it meets the highest safety standards for electrical insulation and protection.

Superior Shrinkage Ratio: With an excellent shrink ratio (typically 2:1 or 3:1), the sleeve conforms tightly to wires, cables, and connectors, offering secure and reliable insulation.

Durability and Strength: Made from high-quality, flame-retardant materials, the sleeve offers robust protection against abrasion, moisture, chemicals, and high temperatures.

Wide Temperature Range: The sleeve operates effectively in temperatures ranging from -55°C to +125°C, making it suitable for a variety of demanding environments.

Easy Installation: The sleeve is simple to apply using a heat gun or oven. It shrinks evenly and predictably, providing a seamless fit around components.

Electrical Insulation: Provides reliable insulation to prevent electrical shorts, voltage spikes, and environmental damage, improving the longevity and safety of electrical systems.

Applications:

Wiring and Cable Protection: Ideal for automotive, electrical, and industrial applications where cables and connectors require reliable insulation and protection from the elements.

Electronics: Used for protecting wires and components in consumer electronics, such as smartphones, computers, and home appliances.

Automotive: Commonly used in the automotive industry for securing wires and protecting electrical connections from heat, moisture, and vibration.

Industrial Equipment: Perfect for insulating wires in manufacturing equipment, machinery, and other industrial systems.

Renewable Energy: Provides protection in solar, wind, and other renewable energy systems, where durability and reliability are critical.

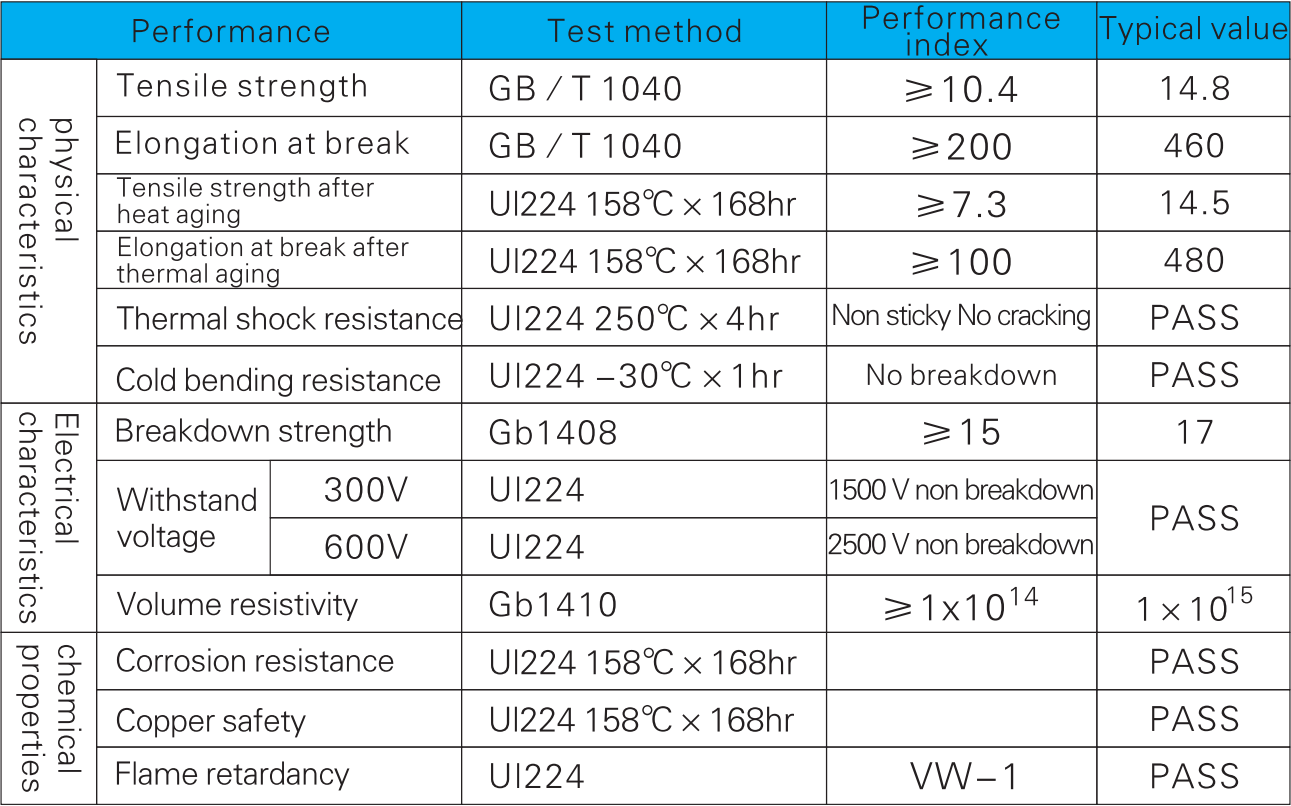

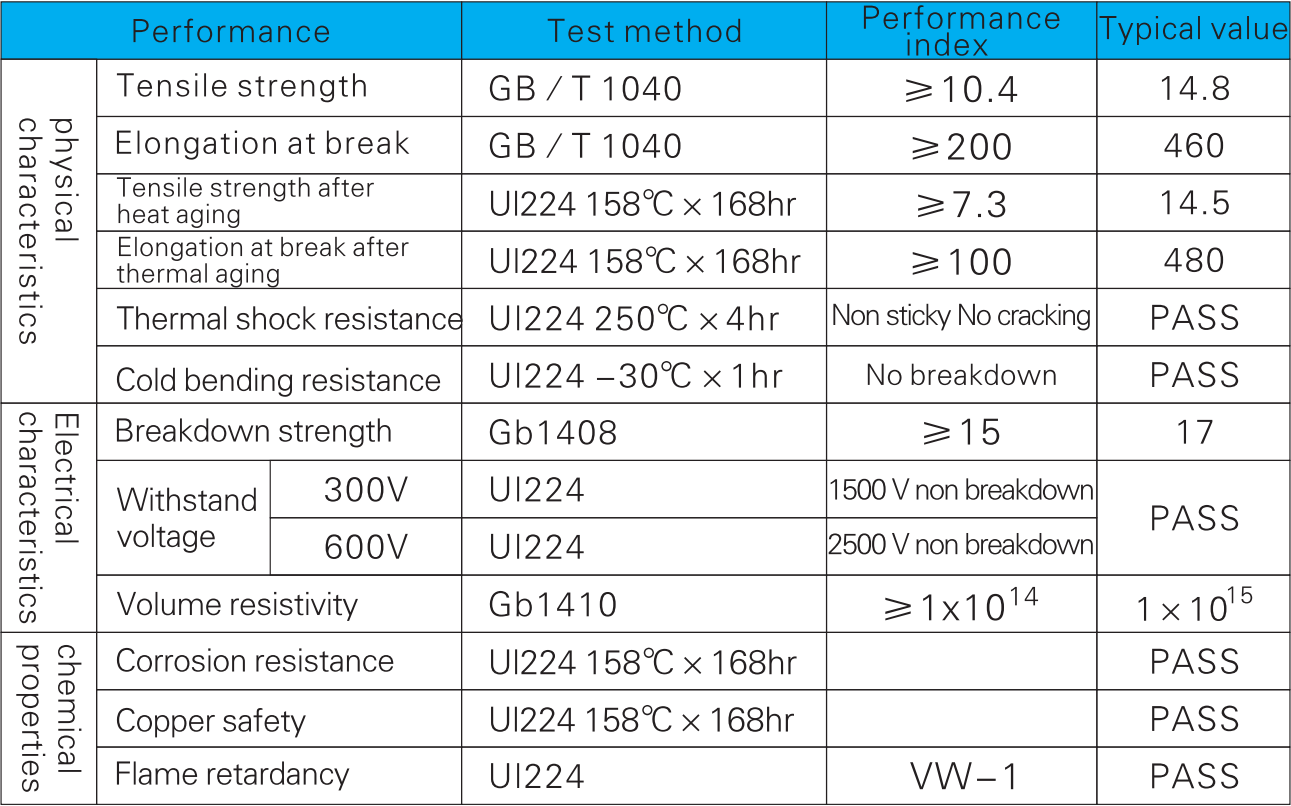

Specification

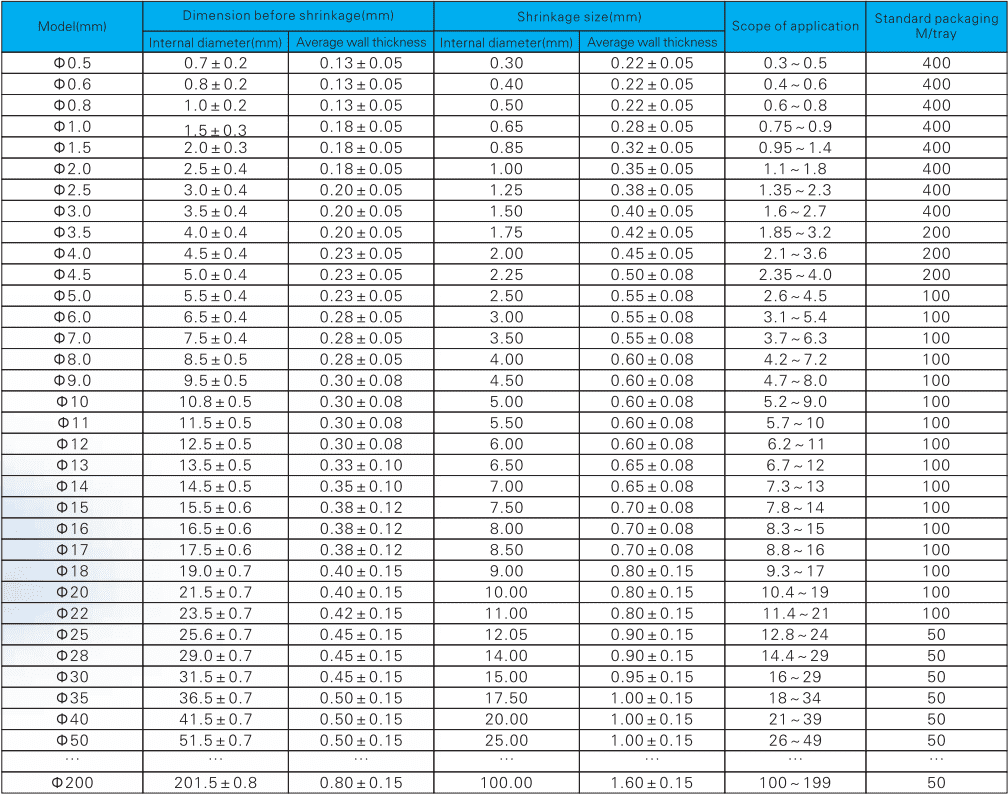

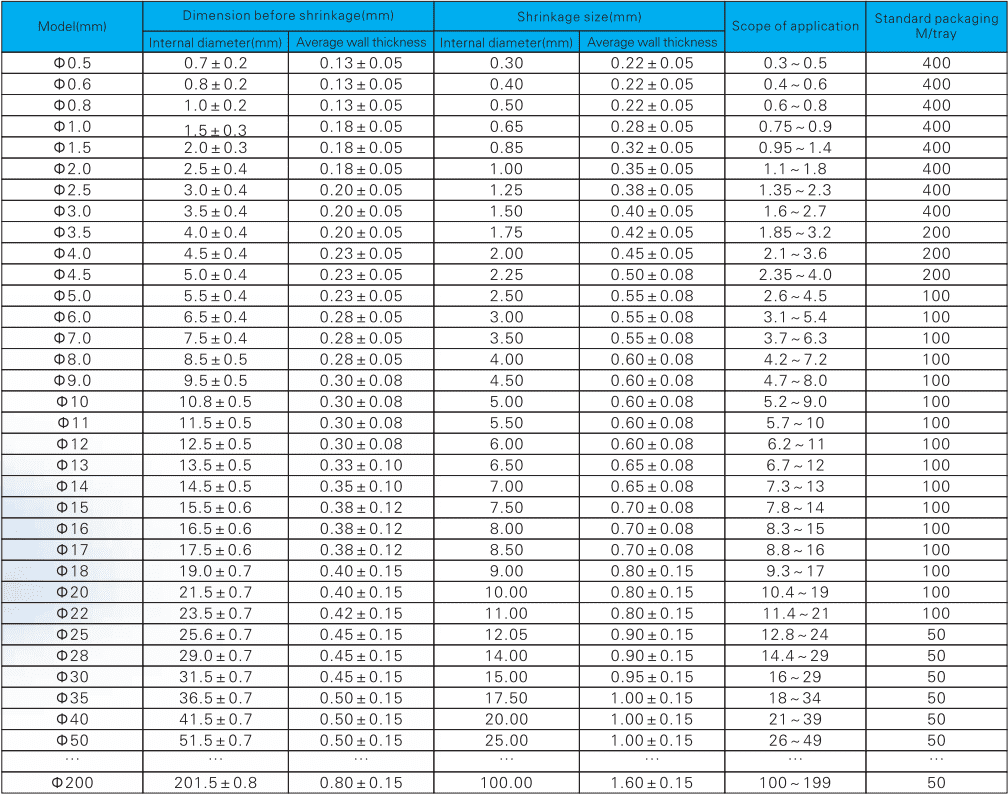

Dimension

Precautions for use:

Preheating temperature control: When installing UL Heat Shrinkable Sleeve, control the preheating temperature to ensure good and uniform shrinkage.

Avoid mechanical damage: During use, avoid scratching or damaging the UL Heat Shrinkable Sleeve with sharp objects, which will affect its insulation and waterproof effects.

Regular inspection: Regularly check the status of the UL Heat Shrinkable Sleeve and replace aging or damaged sleeves in a timely manner to ensure the safety and reliability of the equipment.

FAQ:

1. What is a UL Heat Shrinkable Sleeve?

A UL Heat Shrinkable Sleeve is a heat-sensitive tube that shrinks when exposed to heat, providing insulation and protection for electrical wires, cables, and connectors. It is UL-certified, ensuring it meets industry safety standards for electrical insulation.

2. What is UL certification, and why is it important for Heat Shrinkable Sleeves?

UL certification means that the product has been tested and meets safety standards set by Underwriters Laboratories (UL). For heat shrinkable sleeves, this certification ensures that the product is safe for use in electrical applications and is reliable for insulation and protection.

3. What is the shrink ratio of the UL Heat Shrinkable Sleeve?

The typical shrink ratio of a UL Heat Shrinkable Sleeve is 2:1 or 3:1, which means it can shrink to half or a third of its original size, offering a tight and secure fit around wires and components.

4. What materials are used to make the UL Heat Shrinkable Sleeve?

UL Heat Shrinkable Sleeves are usually made from flame-retardant polyolefin materials, known for their durability, thermal stability, and resistance to chemicals, moisture, and abrasion.

5. How is the UL Heat Shrinkable Sleeve applied?

The sleeve is applied by placing it over the wire or component and then applying heat with a heat gun or oven. The tube shrinks evenly and tightly around the object, providing secure insulation and protection.

English

English