The Ultra Thin Heat Shrinkable Tube is an advanced, highly versatile tube designed for insulation, protection, and encapsulation of electrical components, wires, and cables. Made from high-quality, durable materials, this tube shrinks uniformly when heated, providing a tight, secure fit around the surface it covers. Its ultra-thin profile allows it to be used in applications where space is limited and delicate components require insulation without adding bulk.

Key Features:

Ultra-Thin Profile: The tube’s thin walls allow it to shrink tightly around even the smallest and most delicate components, making it ideal for use in compact devices and assemblies.

High Shrink Ratio: This Heat Shrinkable Tube offers an impressive shrink ratio, ensuring a secure fit around wires, connectors, and other small parts for excellent protection and insulation.

Durability and Strength: Made from premium materials, the tube provides superior resistance to abrasion, chemicals, and environmental factors, ensuring long-lasting performance in harsh conditions.

Thermal Stability: The ultra-thin heat shrink tube remains stable and functional in a wide range of temperatures, from -55°C to +125°C, making it suitable for diverse applications in both high and low-temperature environments.

Electrical Insulation: It provides effective electrical insulation, reducing the risk of short circuits, voltage spikes, and other electrical failures.

Easy to Apply: The tube is easy to apply using a heat source such as a heat gun or oven, and it shrinks evenly and predictably, ensuring a professional-grade finish every time.

Applications:

Wiring and Cable Protection: Ideal for insulating and protecting wires, cables, and connectors in tight spaces, such as in automotive, electronics, and telecommunications.

Electronics and Circuit Boards: Used for protecting delicate components, preventing damage from moisture, dirt, and mechanical stress.

Medical Devices: Perfect for use in medical equipment where small size and reliable protection are crucial.

Consumer Electronics: Commonly used in smartphones, computers, and other compact electronic devices for insulation and protection of wires and internal components.

Automotive: Provides protection for cables, wires, and connectors in automotive systems, preventing wear and tear from heat, moisture, and vibration.

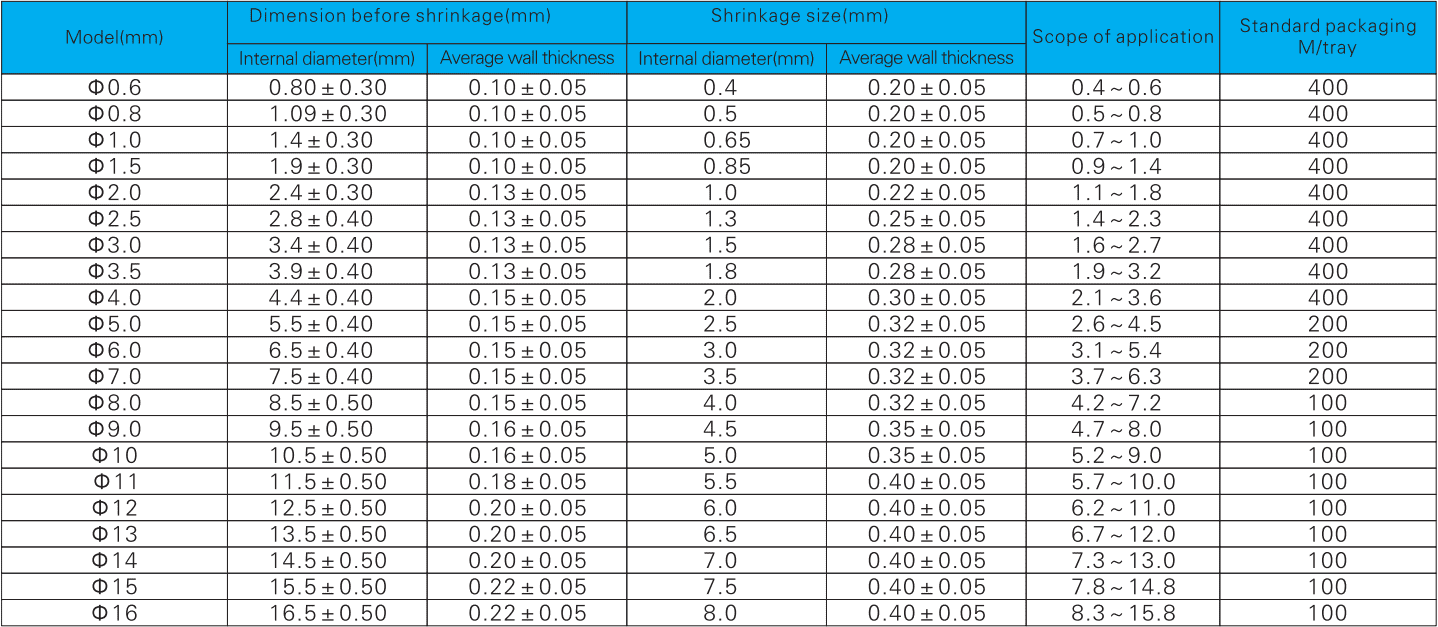

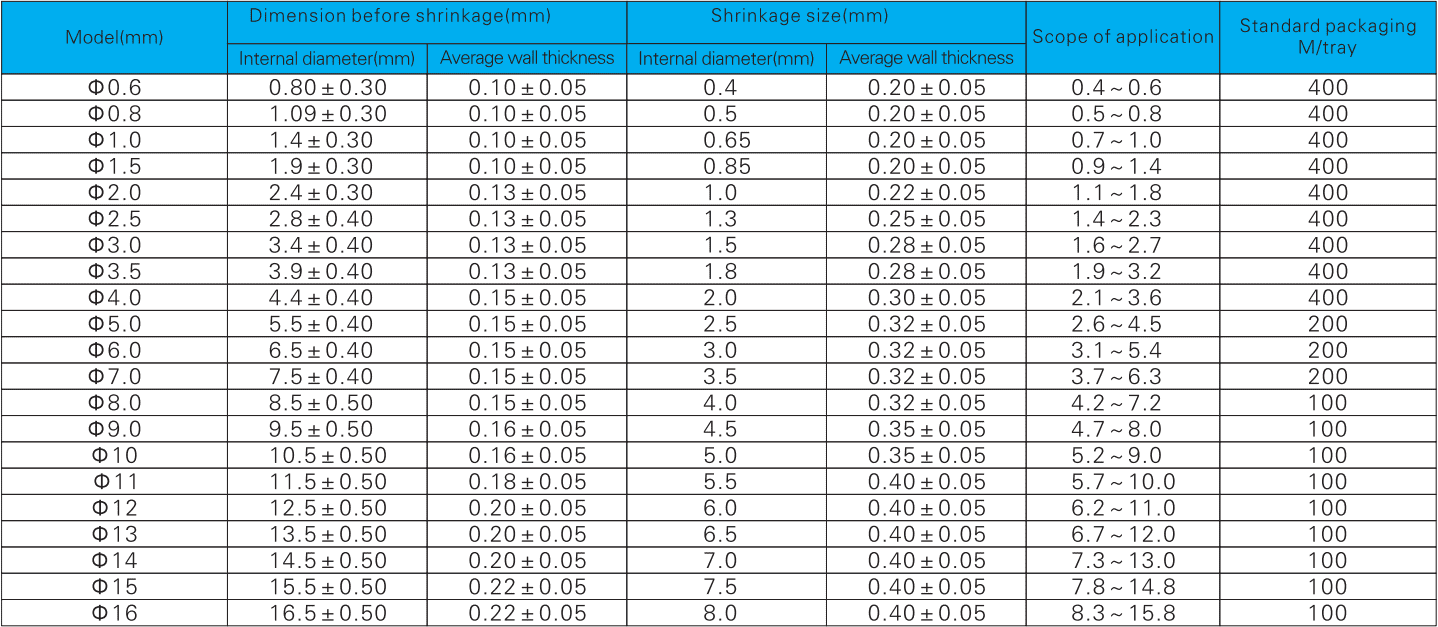

Dimension

Maintenance and care recommendations:

Regular Inspections: Regularly inspect the appearance of the Ultra Thin Heat Shrinkable Tube to make sure there is no visible damage, scratches or cracks. If any problems are found, they should be replaced or repaired in time.

Cleaning: Before installing the Ultra thin Heat Shrinkable Tube, make sure that the surface of the protected part is clean and free of oil and dirt to ensure that the shrink tube can adhere firmly. When it's time to clean the shrink tube, use a mild detergent and a soft cloth.

Waterproof and Dustproof: Make sure the ends of the Ultra thin heat shrinkable tube are completely sealed to prevent moisture, dust, or other contaminants from getting inside the Ultra thin heat shrinkable tube. If necessary, use a heat gun or flame to reheat the ends of the Ultra thin heat shrinkable tube to ensure a complete seal.

Avoid mechanical damage: During installation and use, avoid the Ultra thin heat shrinkable tube being scratched or damaged by sharp objects or sharp edges. Especially around areas that need protection, make sure the Ultra thin heat shrinkable tube is not squeezed or impacted too much.

Storage environment: Ultra thin heat shrinkable tubes should be placed in a dry, ventilated environment when stored, away from direct sunlight and high temperatures. Avoid prolonged exposure of shrink tubing to UV rays to prevent material aging and performance degradation.

Avoid over-stretching: During installation, avoid over-stretching the Ultra thin heat shrinkable tube to avoid rupture or deformation of the shrink tube. Make sure the shrink tube fully covers the area being protected but is not too tight.

Regular replacement: According to the usage and environmental conditions of the shrink tube, regularly inspect and replace aging or severely damaged Ultra thin heat shrinkable tubes. Timely replacement of Ultra thin heat shrinkable tubes can ensure that the protected parts are always in good condition.

Pay attention to safety: When using shrink tubing, be sure to follow relevant safety regulations and operating guidelines to ensure safe operation and avoid fire or other accidents.

FAQ:

1.What is an Ultra Thin Heat Shrinkable Tube used for?

The Ultra Thin Heat Shrinkable Tube is primarily used for insulating, protecting, and encapsulating electrical components such as wires, connectors, and circuit boards. It provides protection from abrasion, moisture, heat, and environmental stress.

2. What materials are used in the production of Ultra Thin Heat Shrinkable Tubes?

These tubes are typically made from high-quality polyolefin, a material known for its excellent thermal stability, durability, and resistance to chemicals and environmental factors.

3. How does an Ultra Thin Heat Shrinkable Tube work?

When exposed to heat, the tube shrinks uniformly, tightly fitting around the component it covers. This shrinkage creates a secure and protective layer that insulates the underlying part, offering protection against electrical short circuits and environmental damage.

4. What is the shrink ratio of the Ultra Thin Heat Shrinkable Tube?

The shrink ratio for most Ultra Thin Heat Shrinkable Tubes is typically 2:1 or 3:1, meaning the tube can shrink to half or a third of its original size, allowing it to fit snugly around various components.

5. What temperature range can the Ultra Thin Heat Shrinkable Tube withstand?

The tube is designed to perform effectively in temperatures ranging from -55°C to +125°C, making it suitable for both high and low-temperature environments, including automotive, industrial, and consumer electronics applications.

English

English